On version 5.4.7.1 (Nov 2024) was introduced a new feature that allows the machining of small chevron seals using the chip less tools. This tool set is normally composed of one inside tool and one outside tool. Since the tool set is relatively large, to avoid collisions the use of those tools is normally limited to seals where the inside is larger than the tool set dimension.

Therefore, machining seals with this set of tools was limited to larger seals where the tool set would fit inside the seal.

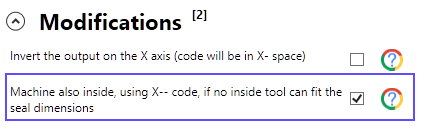

To overcome this limitation and if the machine has a range in X axis that allows the tool to move below the X=0 value, this option was added:

Note: This option is only available on the outside chevron tools

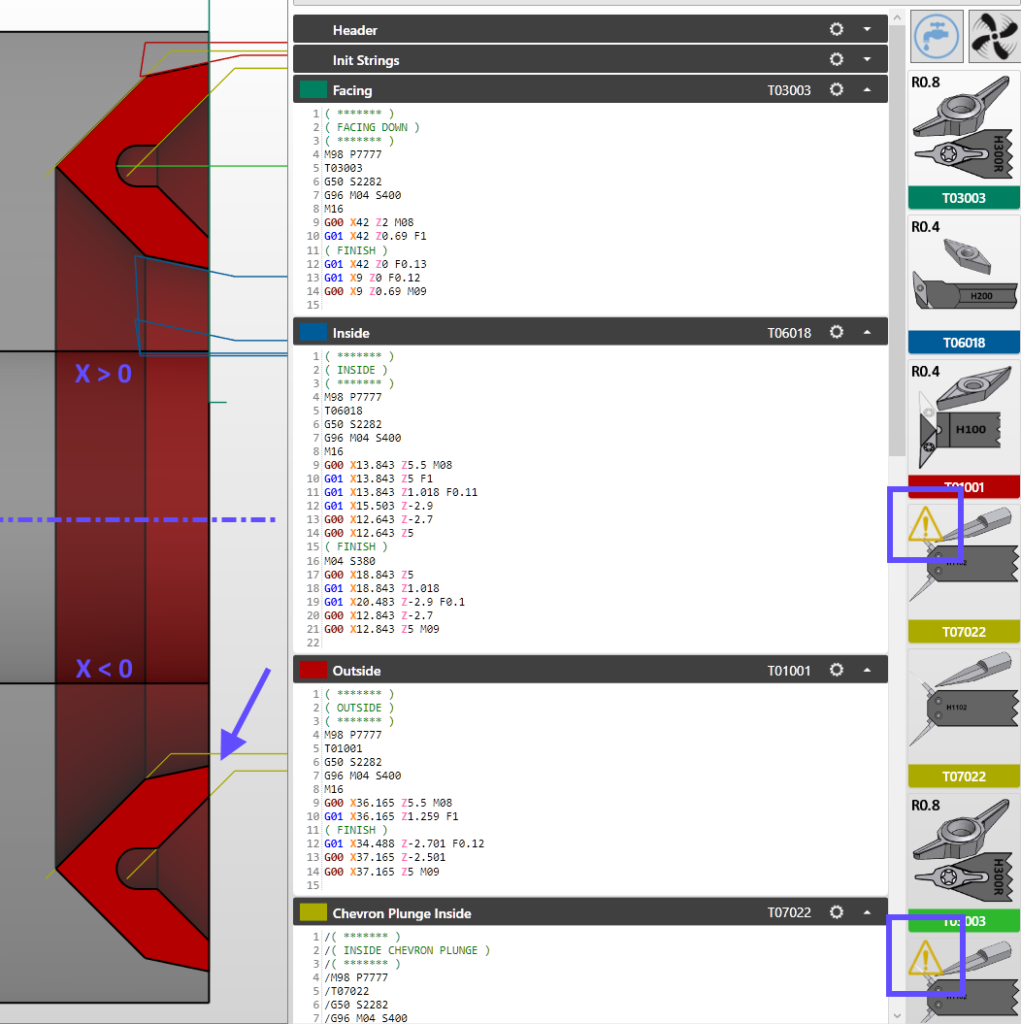

This option will result on the following output:

- If a possible tool exists to machine the inside, no change is made and the standard tool is used

- If no inside tool is available or can fit the inside dimension of the seal, the software will use the outside chevron tool

- The code output will be made on the X– area, meaning that the machine must be able to reach the requested positions

- User must remove the inside insert to avoid collisions with the material. Software will present a warning on the tool icon

The output will be similar to the code below. Special attention to the information on the icon of the tool.