The next tables presents the content of the basic tool package.

The offset number (N) is a unique identifier for the tool that is set on your machine controller.

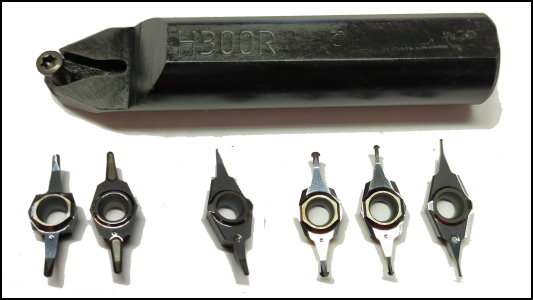

| N | Master tool | Insert | Quantity | Holder | Quantity | Screw |

| 03 | R0.8 or R0.4 | I300 (R0.8) or I301 (R0.4) | 5 | H300R round 20mm | 1 | TS300 (4mm) |

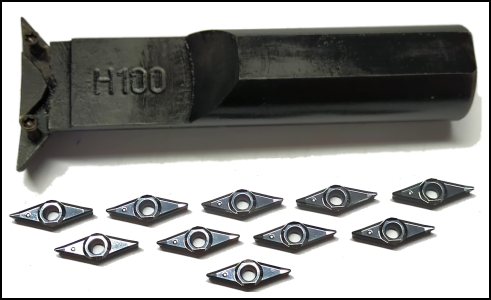

| N | Elastomers machining | Insert | Quantity | Holder | Quantity | Screw |

| 01 13 | Elastomers outside Elastomers inside | I101 (R0.4) | 10 | H100 round 20mm | 1 | x2 TS100 (2.5mm) |

| N | Polymers machining | Insert | Quantity | Holder | Quantity | Screw |

| 08 20 | Polymers outside Polymers inside | I100 (R0.2) | 5 | H100 round 20mm | 1 | x2 TS100 (2.5mm) |

| N | Drill 4mm | Insert | Quantity | Holder | Quantity | Screw |

| 46 | End mill carbide | I460 | 1 | H460 round 20mm | 1 | x1 M5x6 |

| N | Outside groove | Insert | Quantity | Holder | Quantity | Screw |

| 4 15 32 | Groove tool (2.7mm) Angle groove tool (2.7mm) Groove tool (0.9mm) | I401 I403 I411 | 1 1 1 | H401 round 20mm | 1 | TS400 |

| N | Inside groove | Insert | Quantity | Holder | Quantity | Screw |

| 16 33 | Groove tool (2.7mm) Groove tool (0.9mm) | I400 I410 | 1 1 | H400 round 20mm | 1 | TS400 |

| N | Facing/groove/oring | Insert | Quantity | Holder | Quantity | Screw |

| 05 27 14 02 28 | R0.8 (standard or short reach) R0.4 Front oring R1.0 Front oring R0.7 Front oring R0.35 | I500 or I500S I501 I510 I511 I512 | 1 1 1 1 1 | H300R round 20mm | 1 | TS300 (4mm) |

| N | Facing/groove/oring | Insert | Quantity | Holder | Quantity | Screw |

| 12 | R0.8 (standard or short reach) | I502 | 1 | H500 round 20mm | 1 | x2 SS500 |

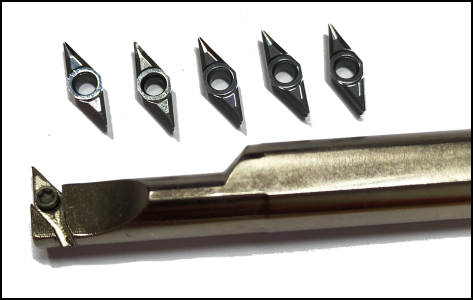

| N | Medium inside tool | Insert | Quantity | Holder | Quantity | Screw |

| 18 | Inside for polymers and elastomers | I200 (R0.4) or I201 (R0.2) | 5 | H200 round 10mm | 1 | TS200 |

| N | Rotary seal tool | Insert | Quantity | Holder | Quantity | Screw |

| 09 47 | Standard rotary seal R1.0 Inverted rotary seal R1.0 | I711 I712 | 1 1 | H700R round 20mm | 1 | TS700 (3.5mm) |

| N | Oring tools | Insert | Quantity | Holder | Quantity | Screw |

| 29/30 07/19 06/17 | Large oring R0.75 Medium oring R0.4 Small oring R0.25 | I700 I701 I702 | 1 1 1 | H700R round 20mm | 1 | SS701 (clamp and screw) |

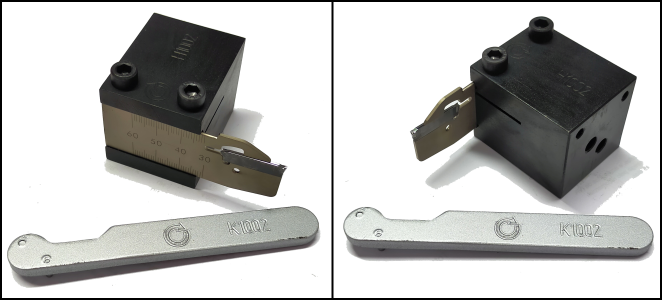

| N | Polymers part off | Insert | Quantity | Holder | Quantity | Screw |

| 34 | Carbide blade, 2 cutting faces 2.0mm | I1002 | 1 | H1002 | 1 | SS1102 (2 units) |

This set up also requires:

- Blade B1102 (that supports the insert)

- Key K1002 (used to open the blade to replace the insert)

- Adaptation (support) to the machine. Since the holder shape is square there is no direct way to hold the H1002 to the machine turret. Contact us for more information

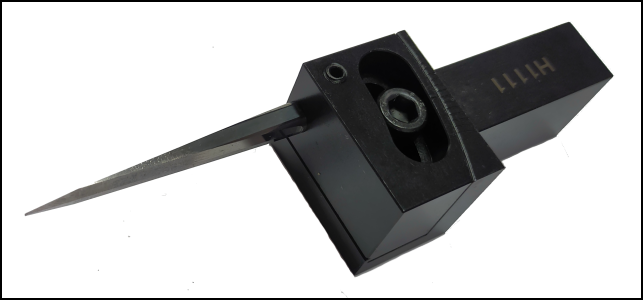

| N | Elastomers part off | Insert | Quantity | Holder | Quantity | Screw |

| 34 | Carbide blade, 60mm long | I1101 | 1 | H1111 | 1 | S1111 (1 unit) |

This set up also requires:

- Adaptation (support) to the machine. Since the holder shape is square there is no direct way to hold the H1111 to the machine turret. Contact us for more information

| N | Small inside machining | Insert | Quantity | Holder | Quantity | Screw |

| 21 | Micro inside R0.3 | I1200 | 1 | H1200 | 1 | S1200 (1 unit) |

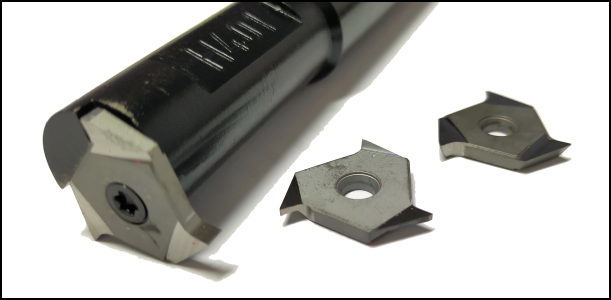

| N | Micro inside machining | Insert | Quantity | Holder | Quantity | Screw |

| 24 | Micro inside R0.2 | I1210 | 1 | H1210 | 1 | S1210 (2 unit) |

| N | Drill 11mm | Insert | Quantity | Holder | Quantity | Screw |

| 25 | Carbide end mill 11mm | I1225 | 1 | – | – | – |

More tools to be added as time permits