In version 5.2.8.0 (August 2022) the FastQuote functionality was added.

The objective is to provide smaller or larger companies a way to create quotes for their customers in the fastest possible way and still have control on how the quote is produced. On this document we will cover all aspects that are import to determine the cost of a item.

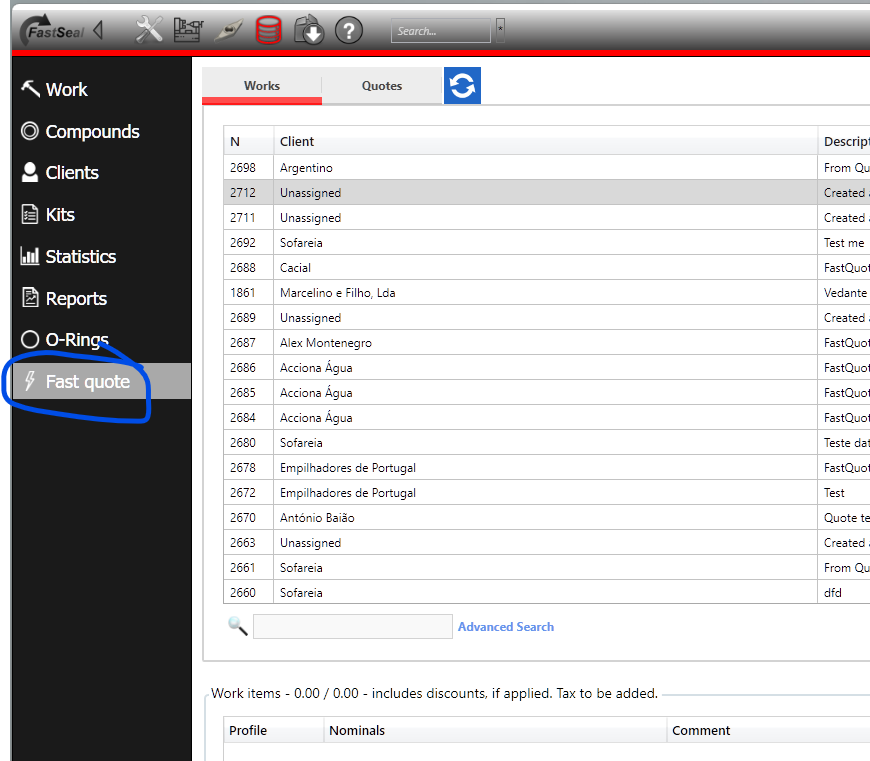

1) Location of the FastQuote

The FastQuote can be accessible in the Database main menu.

2) Initial screen

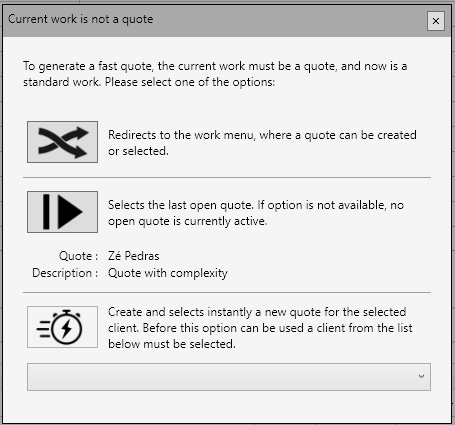

When the FastQuote, and since a quote is to be produced, the software checks if the current work is a quote.

- If the current work is a quote, the FastQuote it immediately open and the user can work on the quoting. When a quote is in progress the following icon is on the main bar:

- If the current work is a standard work, represented by a hammer on the top bar:

the user must start a quote. For this to happen the following dialog was created to speed up things:

The description in front of the three options should be self explanatory. First option takes the user to the work menu, when the user can browse and select the quote looking at the current quotes. Second option simply selects the last quote on the system that is not yet closed. As a third option, a new quote can be started immediately, just by selecting a client from the client list that is present on the combo box list.

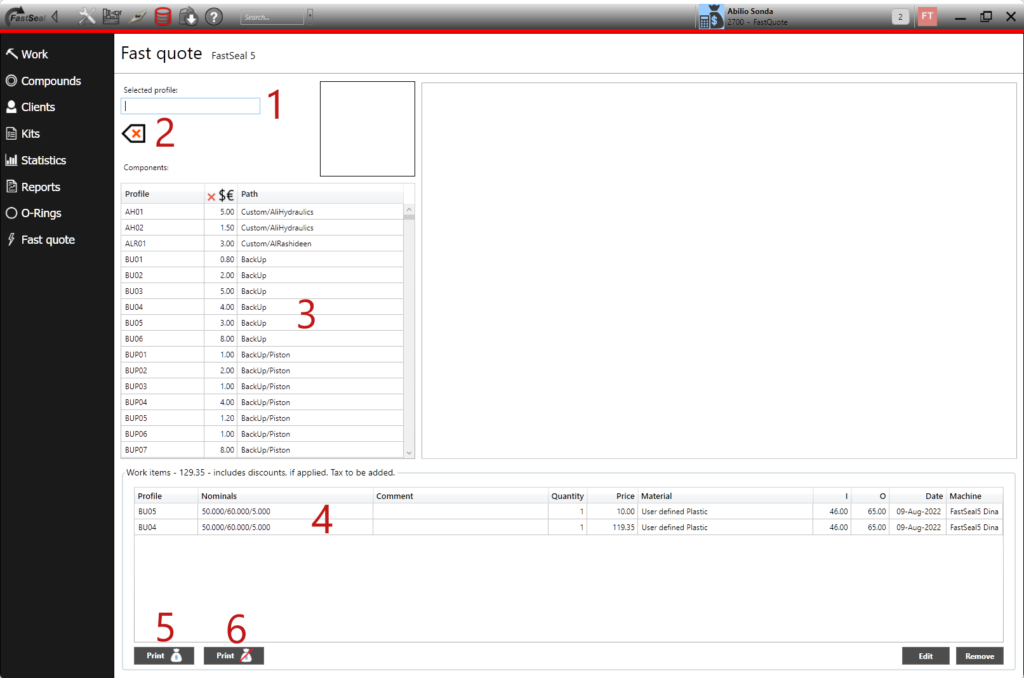

3) FastQuote menu

When the FastQuote is opened the following is present to the user:

- 1 – User can write the profile name directly and the list will be updated filtering the profiles that match what the user is writting

- 2 – Clear the current profile

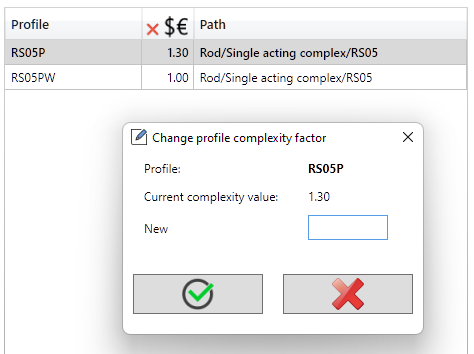

- 3 – Main list of profiles. If the mouse is over one, the profile icon will be shown that helps the profile selection. This list has 3 columns. The first is the profile name, the second is the complexity factor of the profile (right click on it to change the complexity factor). The 3rd is the path of the profile that helps to identify its characteristics.

- 4 – Currently already items on the current quote

- 5 – Prints a work sheet with prices

- 6 – Prints a work sheet without prices

- On the largest area on the right, the interface is presented when a profile is selected.

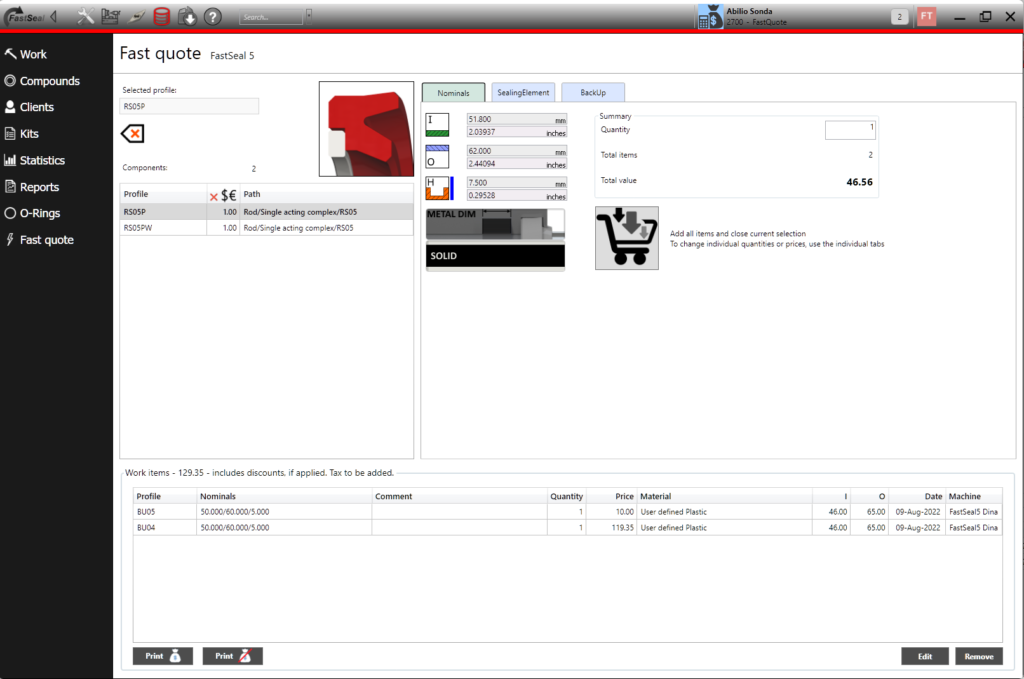

4) Selecting a profile

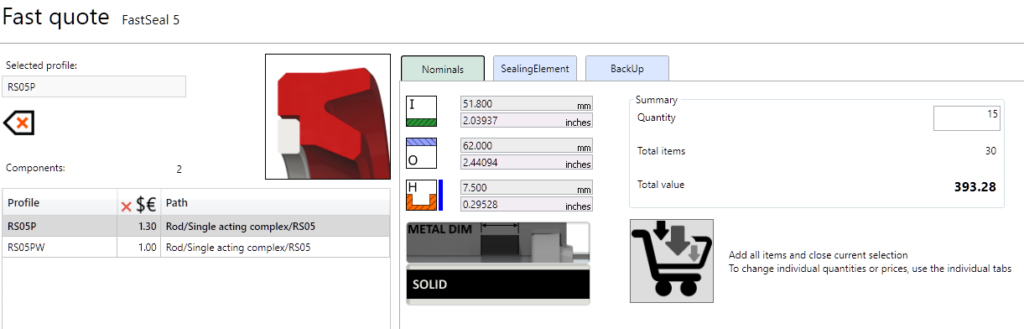

Simple double click on a profile or write its name on the textbox. In this example the RS05P was selected. Since the RS05P has 2 components, 3 tabs where open on the side window:

- Tab 1 – Nominals. This tab is common to all profiles and is the tab when the size of the profile is placed

- Tab 2 – This tab name vary depending on the profile. At least a second tab is present

- Tab 3 – A optional tab, when the 2nd component of the profile is shown. A profile with 6 components would have 6 similar tabs

A quote can be produced just using tab 1, as long all the automatic choices are accepted.

5.1) Tab 1 – Nominals

On tab 1, the basic settings are set: the nominals on the same way as using a normal profile constructor for machining and the quantity.

Automatically the price is shown that is the result of the sum of the prices on the other tabs.

If the user presses the cart button, all the components of this profile are added to the quote, and the profile is closed. User is then returned to the initial screen to select another profile.

For example purposes, the RS05P will be used with a complexity factor of 1.30. 15 parts where also selected:

5.1) Tab 2,3,4,… – Components of the profile

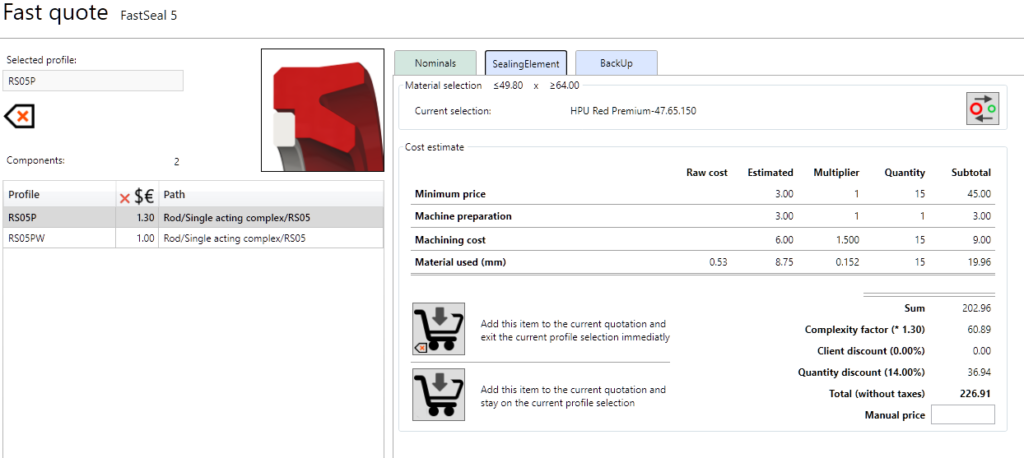

On the next tabs, more control over the price can be obtained. Using the RS05P of the previous menu, the sealing tab (tab 2) should be similar to:

Starting from top to bottom:

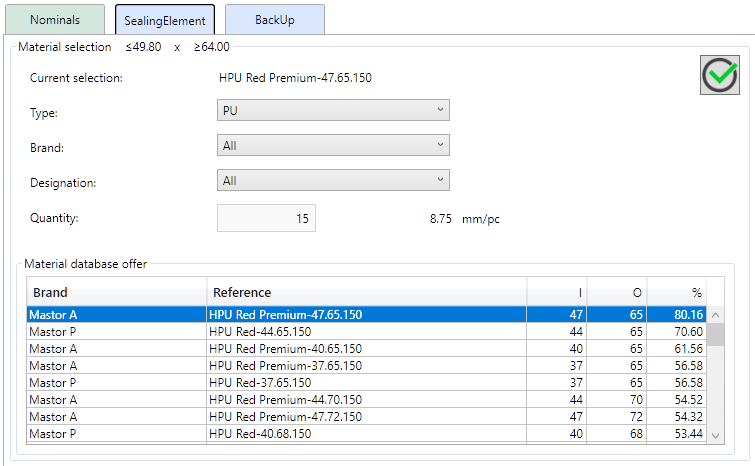

- Material selection: Automatically the software selects the best fit material from the current material database. In this example the material selected was HPU Red Premium – 47.65-150. The use can change the material pressing the button on the top right corner that indicates a material change.

- Below the material list, the cost estimation is present:

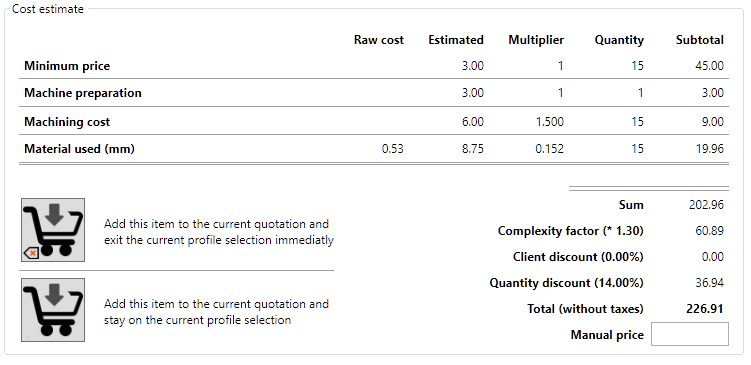

The sub total will be the sum of:

- Minimum price – The minimum price set by the user on the machine settings

- Machine preparation – The cost of preparing the machine that is sent on the machine settings

- Machining cost – that depends on the cost set on the machine settings (per operation)

- Material used – that depends on the material selected (on database with the corresponding stored price). The needed length + extra amount for cutting are taken in account.

This will result on the Sum of 202.96 as presented on the example

After the sub total, others values are added or deducted:

- Complexity factor – in this example, and since the profile has a complexity factor of 1.3, (202.96 * 1.3) – 202.96 = 60.888, that will be added to the total price. If the complexity factor would be 0.8, instead of adding, we will subtract as 0.8 means that the profile is easier than “normal” to be produced. In this case the calculation would be: (202.96 * 0.8) – 202.96 = -40.592 (minus)

- Client discount – if the client had a discount associated on its registration, it will be shown here

- Discount per quantity – as set up on the machine settings

This will produce the Total (without taxes).

The user can also manually set a price that will be used instead of the automatic price.

Settings that affect the cost

There are several settings that affect the calculated cost of a item using the FastQuote system.

a) Complexity factor

The complexity factor of a profile is by default 1. This setting is indented to be changed when the user wants to lower or to rise the cost of a profile. For example producing a back up ring is generally less prone to errors or difficulties than a rod seal that uses exactly the same tools and materials. In this case if the user places 1.1 on the rod seal and leaves 1.0 on the back up, the rod seal will be 10% more expensive than the guide ring.

To change the complexity factor, right click on a profile and the dialog is presented:

b) Machine settings – operation costs

Detailed information regarding the operation costs can be found here.