In this post all steps are shown until reaching the GCode for the popular control Fanuc 0i-MATE.

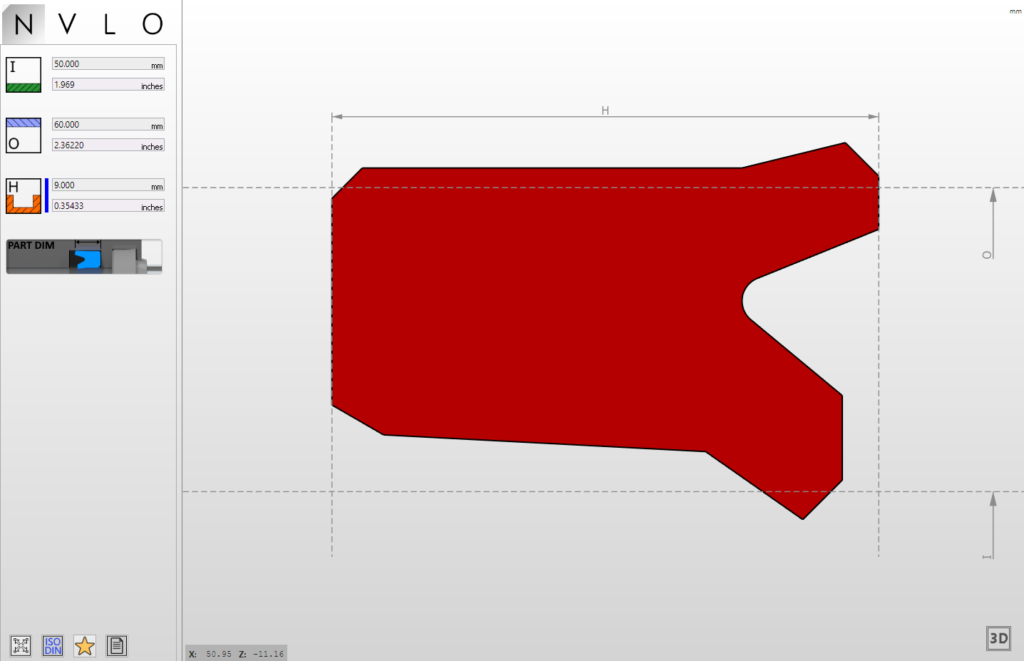

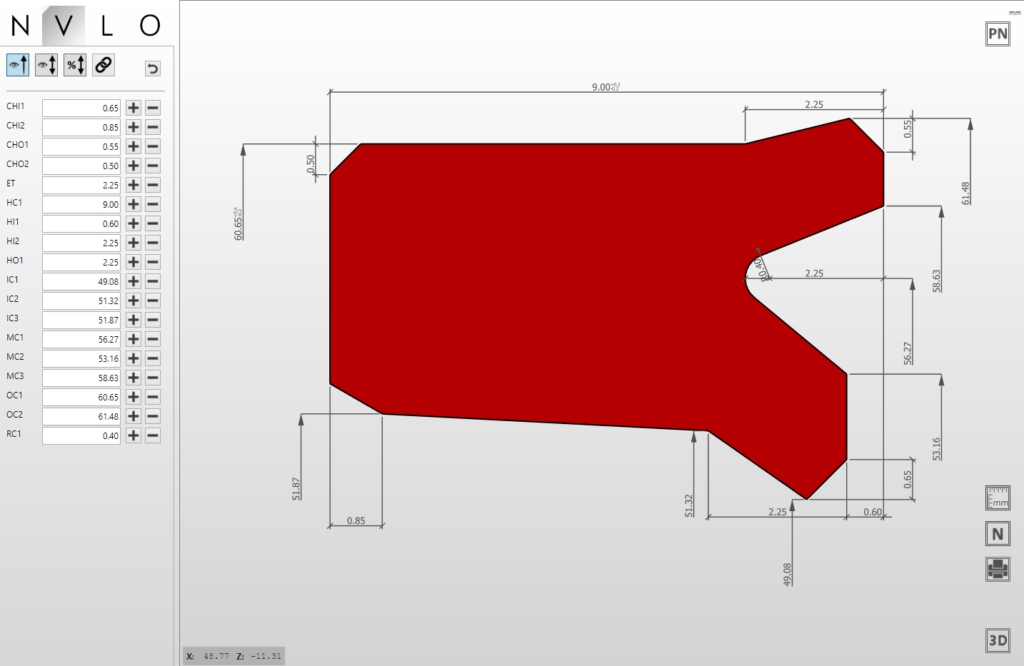

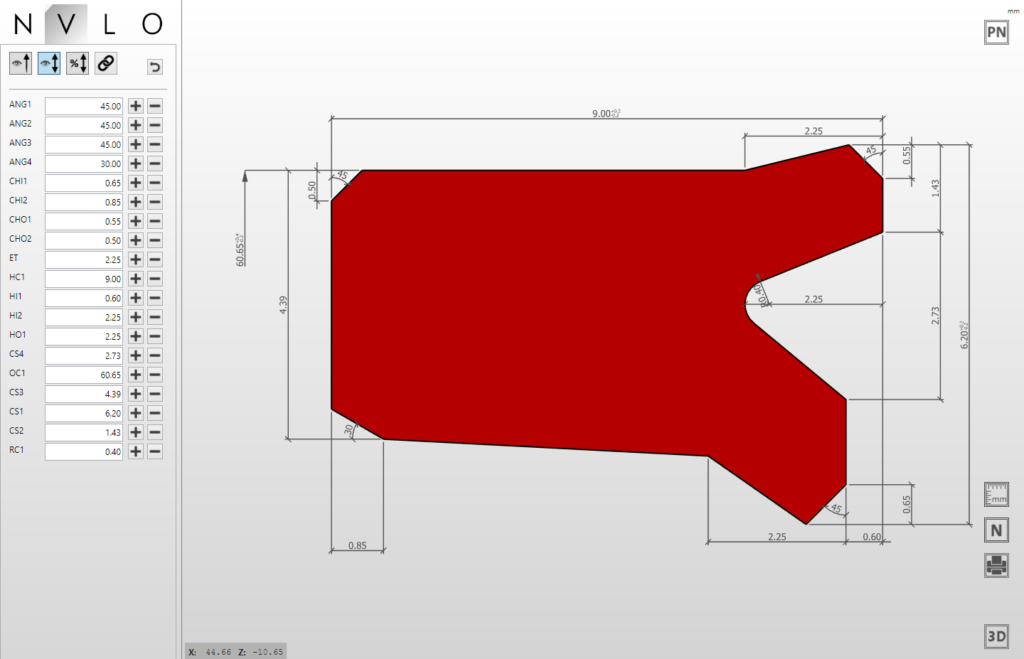

A RS01P 50x60x9-P (rod seal with 9mm height) was selected.

Nominals

Variables

Diameter view

Cross section view

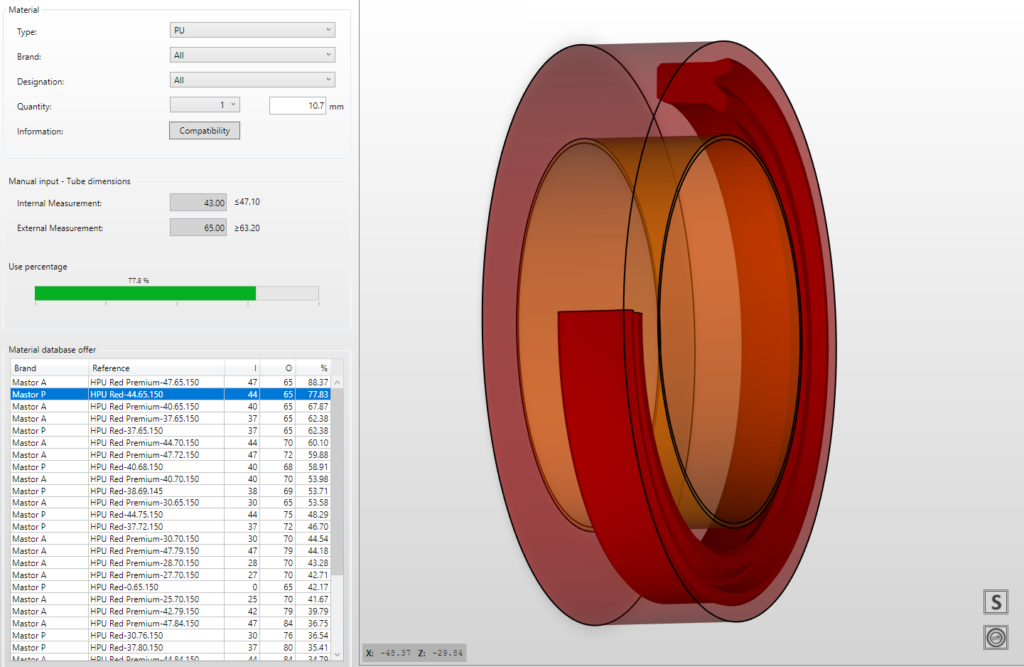

Material selection

GCode

The code can be totally seen below that corresponds to the settings chosen.

The M-codes, header and many other features can be set up on the machine configuration. This means that the code can be adapted to the machine. Comments where added manually to the code below so that it is easier to read.

$O00000101.MIN%

(PROFILE: RS01P-P)

(MEASURES: 50.000/60.000/9.000)

(MATERIAL: HPU RED 44.000/65.000 - TUBE 43.000/65.000)

(STANDARD: YES)

(DATE OF FILE: 20/09/2022 @ 11:53:32)

(FAST SEAL CREATOR VERSION: 5.2.9.2 BUILD 20220919)

(NUMBER OF PARTS:1)

(FASTSEALCREATOR - MASTOR, LDA)

(FANUC SYSTEM CODE A TO 0I MATE TC )

(LICENSED TO UNLICENSED - EVALUATION MODE )

(********************)

( INIT STRINGS )

(********************)

N1 (INITIAL LINE)

IF [VZOFZ - 9.951 LT VNVLZ] GOTO N9999

G50 S3000

CALL O9100

( *********************** )

( FACING DOWNWARD )

( *********************** )

CALL O9100

(FACE GROOVE SMALL)

VNSRX[27]=0.4

VNSRZ[27]=0.4

VNRPN[27]=7

T270527

G50 S2895

G96 S400

M51

G00 X69.800 Z2.000 M89

G01 X69.800 Z0.500 F1.000

G01 X69.000 Z0.500 F0.140

G01 X58.627 Z0.500

G02 X58.264 Z0.456 L0.400

G01 X56.079 Z-0.100

G01 X39.000 Z-0.110

G00 X39.400 Z0.700

G00 X69.000 Z0.700

G01 X69.000 Z0.000

( FINISH )

G01 X69.000 Z0.000

S380

G01 X58.627 Z0.000 F0.120

G02 X58.264 Z-0.044 L0.400

G01 X56.079 Z-0.600

G01 X39.000 Z-0.600

G00 X39.000 Z0.700 M88

( *********************** )

( FRONT GROOVE )

( *********************** )

G50 S2895

G96 S400

M51

G00 X57.684 Z0.500 M89

G01 X56.271 Z-1.250 F0.140

G00 X56.271 Z2.000

G00 X53.369 Z0.500

G01 X56.271 Z-1.250

G00 X56.271 Z2.000

G00 X58.491 Z0.500

( FINISH )

G01 X56.271 Z-2.250 F0.120

G00 X56.271 Z2.000

G00 X51.710 Z0.500

G01 X56.271 Z-2.250

G00 X56.271 Z2.000 M88

( *********************** )

( INSIDE )

( *********************** )

VTOFX[13]=-37.980(13)

VTOFZ[13]=0.906(13)

CALL O9100

(INSIDE ELASTOMERS MACHINING)

VNSRX[13]=0.4

VNSRZ[13]=0.4

VNRPN[13]=2

T130113

G50 S2895

G96 S400

M51

G00 X44.735 Z2.500 M89

G01 X44.735 Z0.744 F1.000

G01 X44.735 Z0.344 F0.140

G01 X43.000 Z-0.524

G01 X43.000 Z-3.150

G01 X43.329 Z-3.385

G01 X43.867 Z-8.571

G02 X43.973 Z-8.750 L0.400

G01 X45.033 Z-9.651

G00 X41.800 Z-9.451

G00 X41.800 Z0.344

( FINISH )

G00 X52.735 Z0.344

G01 X45.313 Z-3.367 F0.120

G00 X46.427 Z0.121

G01 X51.329 Z-3.385

G01 X51.867 Z-8.571

G02 X51.973 Z-8.750 L0.400

G01 X53.013 Z-9.651

G00 X42.000 Z-9.451

G00 X42.000 Z5.000 M88

( *********************** )

( OUTSIDE )

( *********************** )

CALL O9100

(OUTSIDE ELASTOMERS MACHINING)

VNSRX[1]=0.4

VNSRZ[1]=0.4

VNRPN[1]=3

T010101

G50 S2895

G96 S400

M51

G00 X57.125 Z2.500 M89

G01 X57.125 Z1.383 F1.000

( FINISH )

G01 X65.264 Z-2.667 F0.120

G00 X62.436 Z0.955

G01 X60.646 Z-2.698

G01 X60.646 Z-8.900

G03 X60.412 Z-9.183 L0.400

G01 X59.476 Z-9.651

G00 X62.479 Z-9.451

G00 X62.479 Z5.000 M88

( *********************** )

( CUTTING )

( *********************** )

M50

CALL O9100

(ELASTOMERS PART OFF)

VNSRX[11]=0

VNSRZ[11]=0

VNRPN[11]=8

T111111

G50 S2895

G96 S350

G00 X65.479 Z3.000 M89

G00 X65.479 Z-9.000

G01 X50.847 Z-9.000 F0.140

G00 X65.479 Z-9.000 M88

G00 X65.479 Z15.000

(********************)

( ZERO POINT )

(********************)

VZOFZ=VZOFZ-9.951

/ M05

/ CALL O9100

/ T030303

/ GOTO N9999

CALL O9100

GOTO N1 (REPEAT)

N9999

M30

%