The standard, first movement, for each tool is in the form of a fast X and Z movement, similar to:

G00 X50 Z2This movement normally does not cause any issue if the tool change is made far away from the material on the Z++ direction. However there are configurations that require a different approach, more exactly machines where the tools are placed side by side (linear tools) and becomes safer to move first the X coordinate then the Z coordinate. The previous movement becomes:

G00 X50

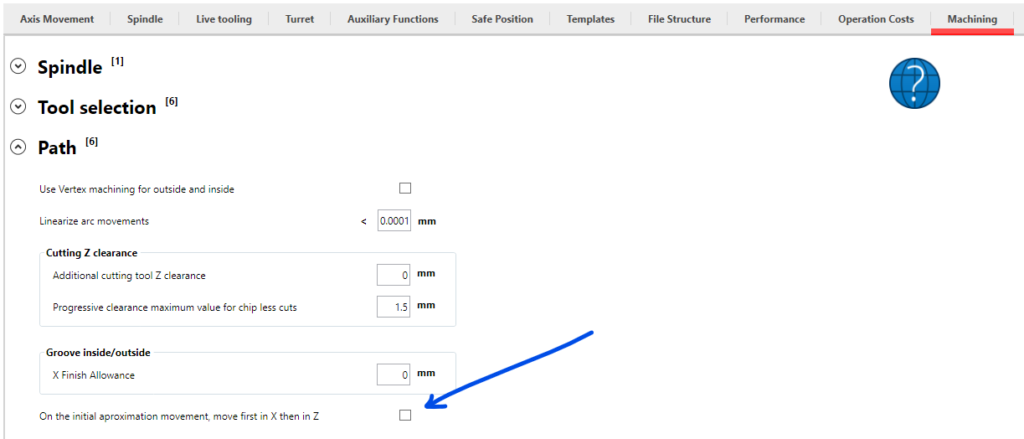

G00 Z2This option is located on the machining settings, under the path subsection:

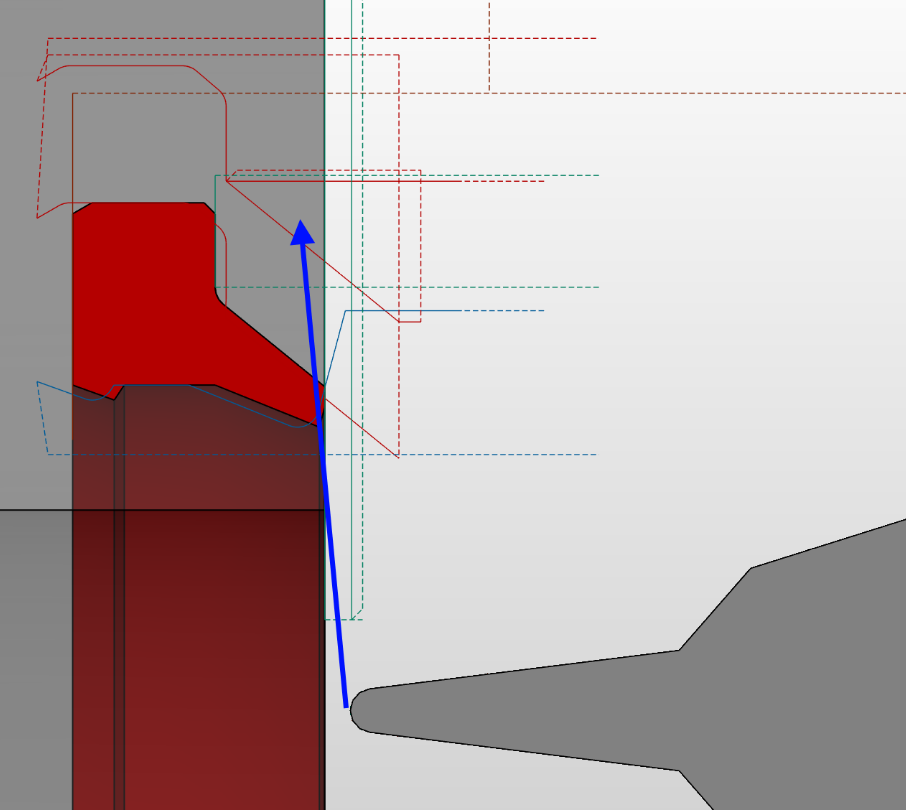

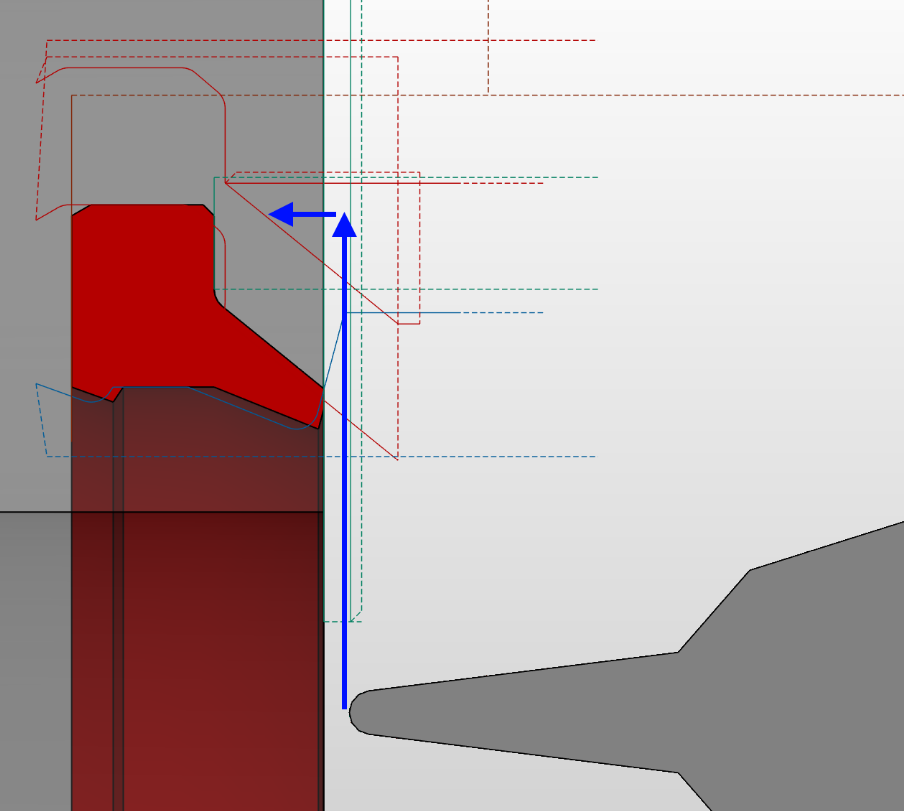

The following example illustrates the situation where this option is useful: