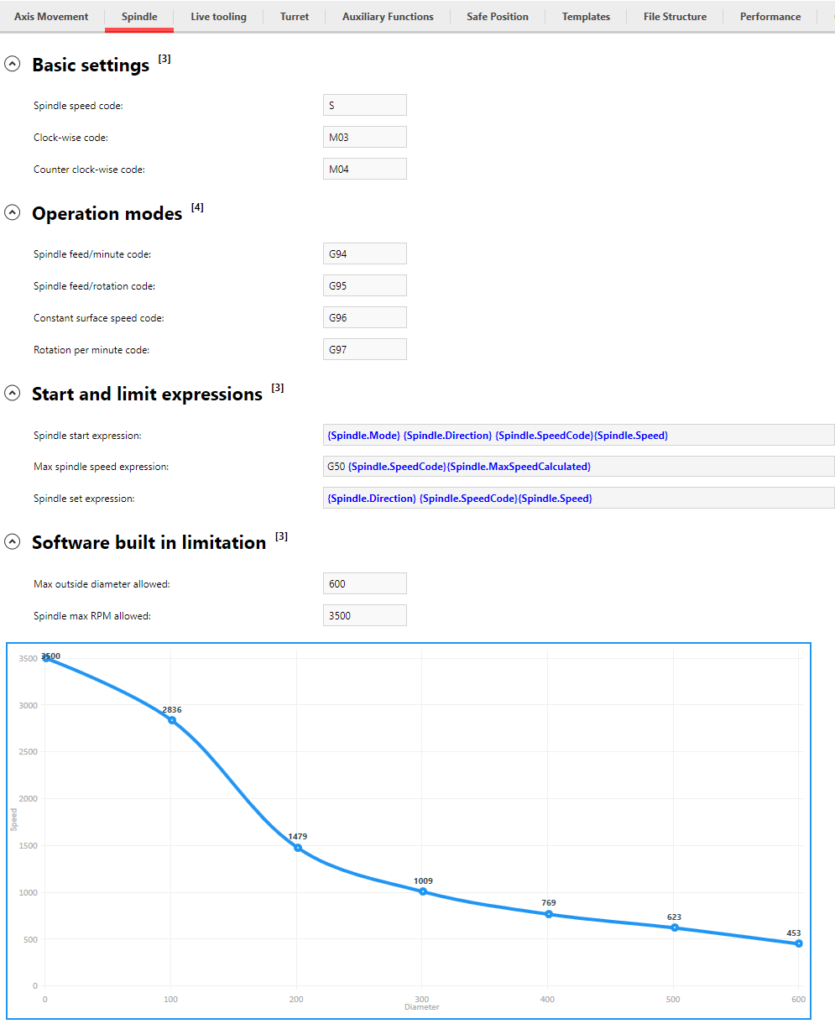

The settings on this section are related with the basic spindle control and also, depending on your machine, to set a limit on the spindle speed.

Basic section

On the basic section the codes that your machine use to set the spindle speeds, and directions (clock wise and anti clock wise) should be placed. Note that normally the clock wise and anti clock wise are seen from the motor rear. The previous image contains the most common settings among machine manufacturers.

Operation modes

On operation modes two diferent groups of modes are set:

Feed mode: feed/minute and feed/rotation that can also be read as units/minute and units/rotation. Since the code output is always in milimetres, this can be seen as mm/minute and mm/rotation.

Spindle mode: Constant surface speed and fixed rotations/minute. Since the output is in milimetres, the constant surface speed units are meters/minute. For example 400 means that the spindle will try to rotate at a determined RPM so that the tooltip is cutting the material at 400 meters/minute, independently of the diameter of the cut. This is why the spindle RPM’s vary depending on the diameter.

Start and limit expressions

Spindle start expression

The complete line to start the spindle should be placed, making use of the previous settings.

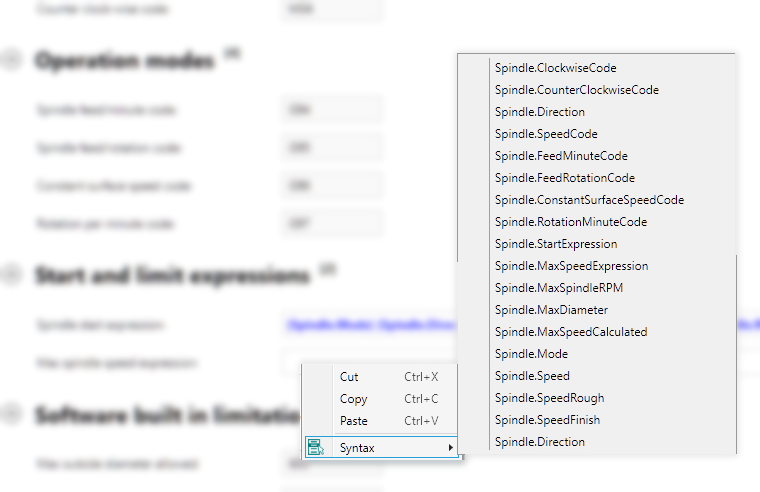

Pressing right click on the mouse, the “syntax” menu appears and the “reserved words” can be used, for example, several “reserved words” are available to be used:

Max spindle speed expression

The max spindle speed expression, is the expression (if any) to be used to limit the maximum spindle speed. It is often mandatory, due to safety, to be used together with a constant surface speed command, as it can put in danger the fixing of a material if the speed exceeds a determined value.

This expression can contain a fixed value (example below, to set 1500 rpm as max, on a Fanuc machine)

G50 S1500or it can contain a value that is calculated depending on the material diameter, making use of the option on the next section (software built in limitation), and this would become (recommended):

G50 S{Spindle.MaxSpeedCalculated}Spindle set expression

The spindle set expression was introduced in version 5.4.2.5

On some machines controllers when a spindle speed is requested to be changed, the standard S(spindle value) when alone is not accepted and more complex codes combination of codes are needed. Therefor the spindle set expression was implemented, and it is used internally when a just the spindle speed is to be changed (no change on direction or spindle mode). For example when the finish spindle speed of a tool is different from the rough spindle speed, this setting is used.

Software built in limitation

To reach higher spindle speeds on smaller diameters and limit the spindle rotation on larger ones a fixed value for the max spindle rotations is not suitable, therefor the options on this section were added, where the user informs the maximum diameter that the machine can process and the maximum possible spindle speed. After those values are introduced, a graph is presented where the user can define his maximum spindle speeds depending on the diameter. It is recommended that a down curve type is set, similar to the one present on the initial screen of this page.