GrooveTurn machining is now available, exclusively on the PISTON01 profile, located in the metal section.

This machining methodology has many advantages over the standard machining, as one single tool can produce complex shapes. In the example video the outside of a piston is fully started and finished by the same tool. Part off is also possible if the cross section is within the range of the tool. With a standard machining methodology, three different tools would probably be used.

For the manufacturer it represents savings in machining time, set up and also in finish quality as there is no overlapping between several tool path’s.

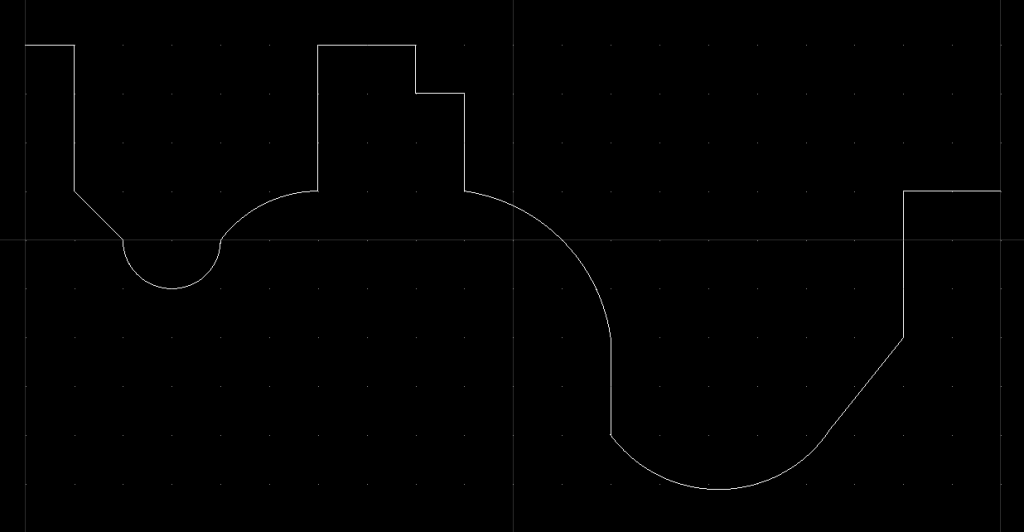

The complete tool path was generated automatically based on the selected tool, and follows the insert manufacturer recommendations, with proper retract movements before the groove progression.

The tool selection, as the remaining machining processes built on the software, is also done automatically based on the tool database maintained by the software user.

Early, internal tests

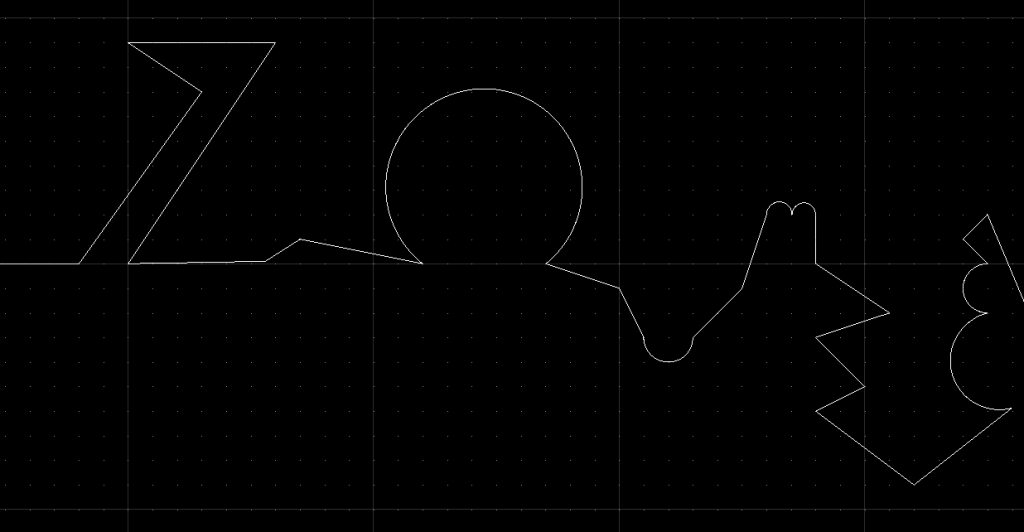

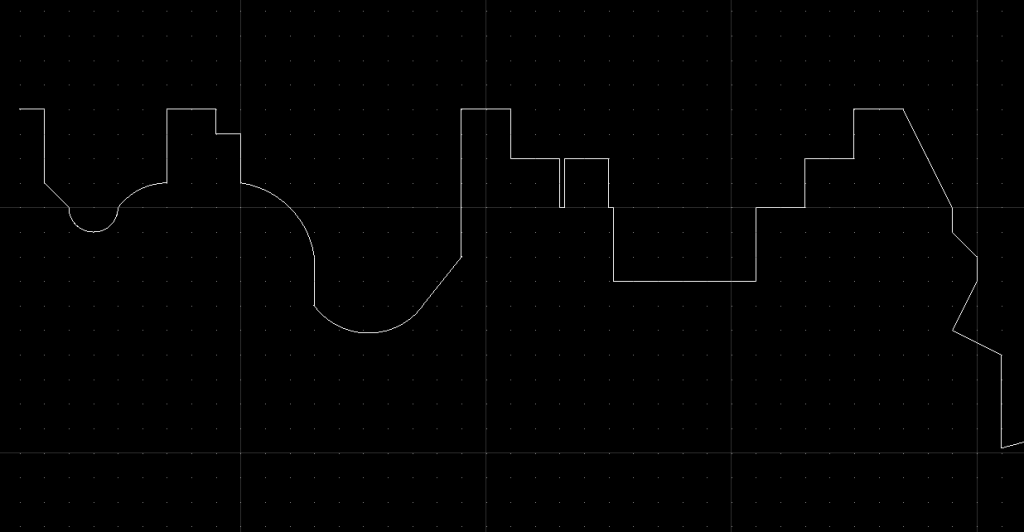

During the early stages of the groove turn tests, very complex shapes were placed under testing before we released a version including the proposal groove turn algorithm. Some of the complex tests used to test our algorithm were:

Next improvements

Currently only the outside groove turn is available, that is considered under testing. After the outside turn groove is considered stable the inside turn groove, that is very similar in terms of implementation will be released.