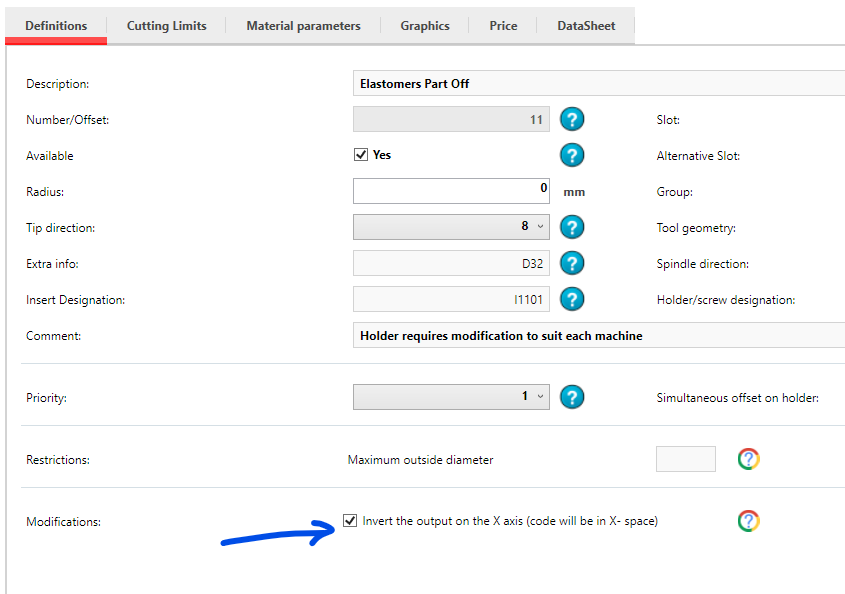

On legacy machines, like the Economos IP4500/IP5000 series some of the movements need to be done on the X negative values due to the tools arrangement and the maximum diameter capability (IP4500 up to 450mm and IP5000 up to 500mm). For example the part off tools are generally installed on the lower portion of the linear tool holder. The part off tools are then generally prepared to cut from the outside to the inside direction, while programmed in X negative. To enable this option simply check the corresponding box, on the corresponding tool, under the tool database:

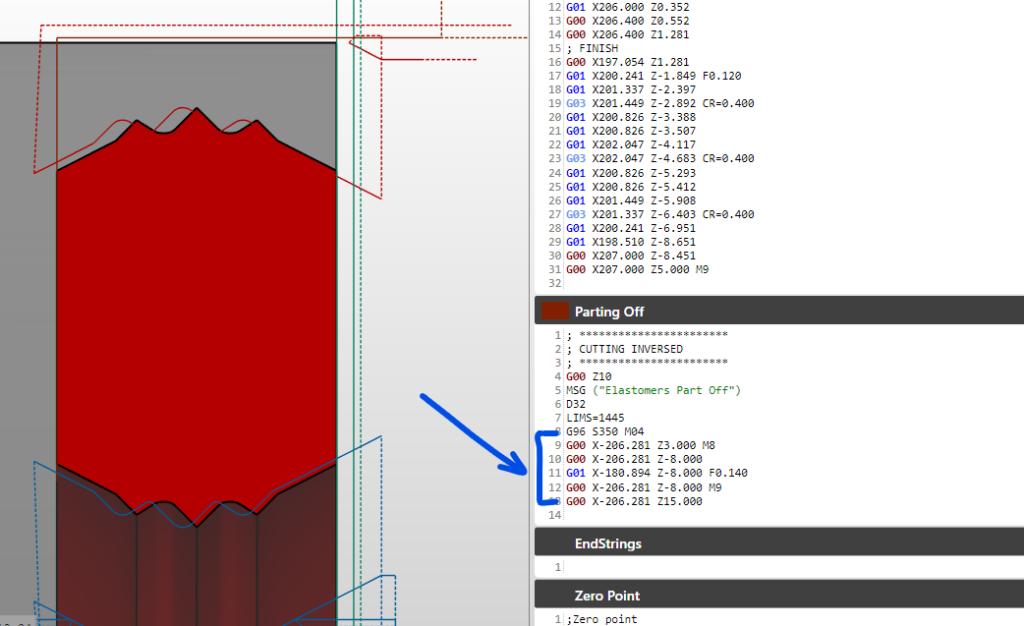

This feature (version >=5.3.0.9) implements this cutting method so that our clients can use the machine models that require them. Below the output of such cutting scheme is present.

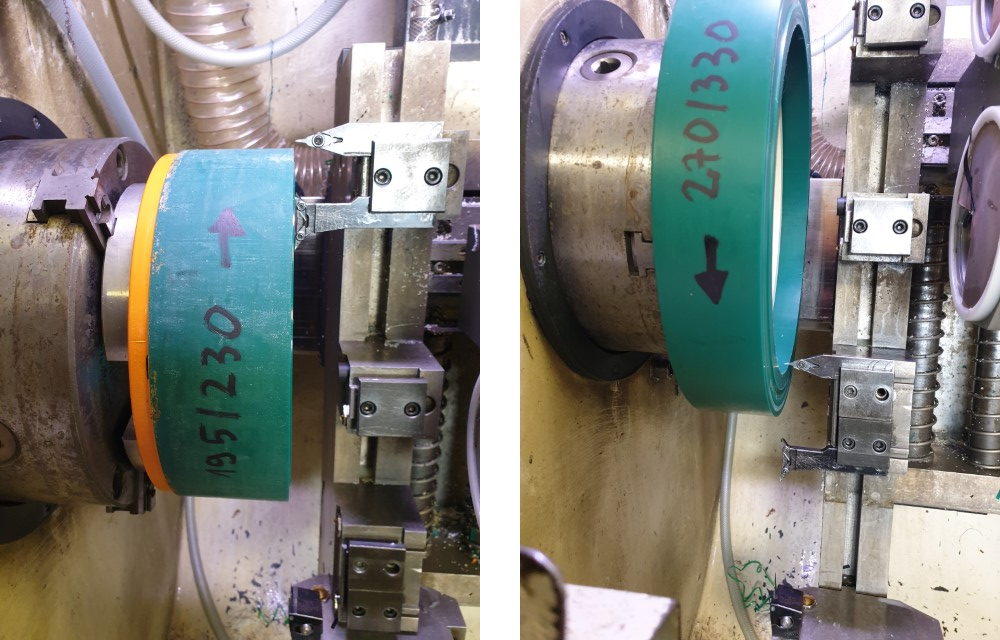

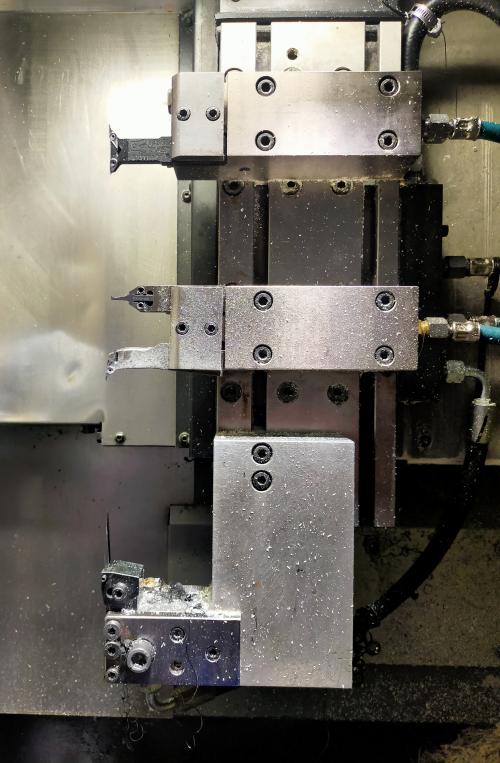

This kind of set up is generally similar to:

Since now the selection of the inverted code is fully dependable on the selected tool, the output code can be a mixture between inverted code and non inverted code fully corresponding to all combinations. This possibility together with the ability to choose a tool based on a machining diameter can even lead to configuration where the chuck rotates in one direction. See examples below, courtesy of a client: