On this section the auxiliar functions that are available on your machine are set. If your machine does not have some of the functions, leave the text boxes empty

Coolant

Generally M08 and M09 are the start and stop commands for coolant. Change to any other that suits your machine.

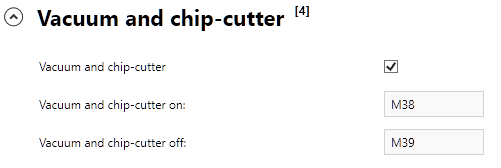

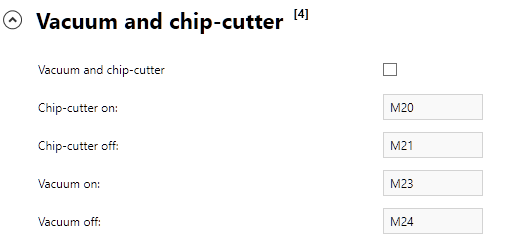

Vacuum and chip-cutter

If your machine have both a vacuum and a chip cutter and both are turned on and off with the same M code, select the option “Vacuum and chip cutter”. If the machine only have a vacuum or if it has dedicated M codes for the chip cutter.

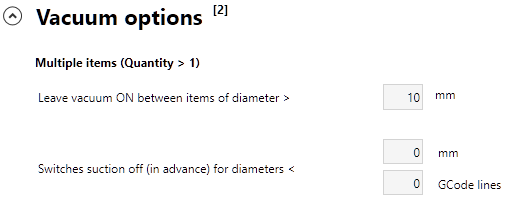

Vacuum options

In this section, some extra control is possible over the vacuum (that also affects the cutter)

The first option is to leave the vacuum ON when several parts are being produced. This saves energy as normally the start of the vacuum is energy demanding. Since the vacuum can also catch small seals, the option have the possibility of defining the diameter from witch the option should be used. If the user selects, for example 50mm, all parts below 50mm will have the vacuum off before part off. For all other dimensions, the vacuum is left ON.

The section option will trigger the instruction to turn off the vacuum (when appliable), a determined number of lines before the cutting. This option is useful when the vacuum is very powerful and the machine is very fast, meaning that there is still a possibility of having a strong air flow during the cut, even with the vacuum turned OFF. By anticipating the vacuum OFF instruction, more time will exist so that the air flow is lower during the part off.

Air blast

Air blast is the option to use air to clean the tools. It is generally applied after a tool is used, and before a tool change. If this option is available, the codes should be set here, and then they can be used on the tool change template (and others).

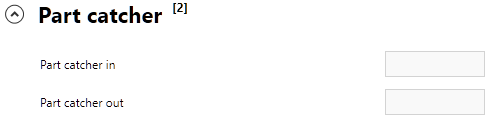

Part catcher

Normally machines with serial production and with a bar feeder have a part catcher. Their M codes should be set on this section.