The bar feeder, also known as a bar loader is a separated accessory, placed behind the lathe chuck, for serial production with the objective of supplying a near continuous operation to the lathe. This is done by opening the chuck and push the raw material then closing the chuck again. The options be below allow this type of control.

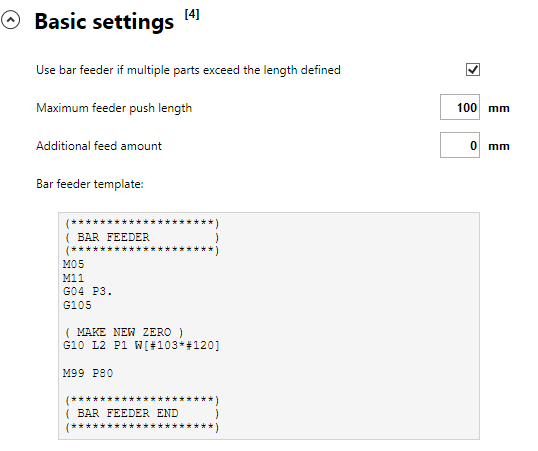

The available settings are the following, and should be used together with the available templates so that a suitable configuration is made as variables and conditions must be set that enable or not the use of the bar feeder.

This setting and the other templates settings, on a Haas ST35 with a bar feeder, making 10 guide rings with 50×60 and 10mm height produces the following code. One push is made by the bar feeder as the total length requires more than 100mm but less than 200mm.

%

O0801 (GR01-MPS 50.000/60.000/10.000)

(PROFILE: GR01-MPS)

(MEASURES: 50.000/60.000/10.000)

(MATERIAL: POM 46.000/62.000 - TUBE 46.000/62.000)

(DATE OF FILE: 23/02/2023 @ 12:24:44)

(FAST SEAL CREATOR VERSION: 5.3.1.1 BUILD 20230222)

(******* BAR FEEDER *******)

(PART COUNTER)

#110 = 0

(NUMBER OF PARTS:10)

#100 = 10

(BAR FEEDER MAX LENGTH: 100)

#101 = 100

(BAR FEEDER ADDITIONAL LENGTH: 0)

#102 = 0

(REQUIRED MATERIAL PER UNIT:12.85)

#103 = 12.85

(TOTAL MATERIAL REQUIRED:128.5)

(WILL BAR FEEDER BE USED?:)

(YES - SEE RECOMMENDED SETTINGS BELOW)

(NUMBER OF PARTS THAT FIT PER PUSH: 7)

#105 = 7

(TOTAL PUSHES: 1)

(BARFEEDER PUSH LENGTH D: 89.95)

(FASTSEALCREATOR - MASTOR, LDA)

(HAAS ST35 BARFEEDER )

(LICENSED TO UNLICENSED - EVALUATION MODE )

(STANDARD: YES)

(********************)

( INIT STRINGS )

(********************)

G99 (FEED PER REVOLUTION)

G21

G54

G00 G40 W50.

N80

(PARTS TO BE MADE ON CURRENT MATERIAL)

IF[ [#100-#110] GE #105 ] #120=#105

IF[ [#100-#110] LT #105 ] #120=[#100-#110]

(START AND WAIT FOR VACUUM BEFORE EACH SERIES)

M31 (VACCUM ON, WITH PAUSE)

G04 P3.

N140

M97 P100 L#120

IF [#110 GE #100] M99 P150 (DONE)

G10 L2 P1 W87.85

G105 (USES SET MANUAL BAR FEEDER VALUES)

M99 P140

N150

M30 (PROGRAM END)

(PART PROGRAM START)

N100

( ******* )

( FACING DOWN )

( ******* )

G53 X0 Z0

T0303

G50 S[#130+250]

G96 M04 S#130

M31 (VACUUM ON)

G00 X66.000 Z2.000 M08

G01 X66.000 Z0.690 F1.000

( FINISH )

G01 X66.000 Z0.000 F0.140

S380

G01 X42.000 Z0.000 F0.120

G00 X42.000 Z0.690 M09

( ******* )

( INSIDE )

( ******* )

G53 X0 Z0

T0820

G50 S[#130+250]

G96 M04 S#130

M31 (VACUUM ON)

G00 X48.337 Z2.500 M08

G01 X48.337 Z1.641 F1.000

G01 X48.337 Z1.441 F0.140

G01 X46.000 Z0.283

G00 X44.800 Z0.483

G00 X44.800 Z1.441

( FINISH )

G00 X54.317 Z1.441

G01 X50.117 Z-0.659 F0.120

G02 X50.000 Z-0.800 R0.200

G01 X50.000 Z-9.400

G02 X50.117 Z-9.541 R0.200

G01 X51.700 Z-10.333

G01 X51.700 Z-12.550

G00 X45.000 Z-12.350

G00 X45.000 Z5.000 M09

( ******* )

( OUTSIDE )

( ******* )

G53 X0 Z0

T0808

G50 S[#130+250]

G96 M04 S#130

M31 (VACUUM ON)

G00 X61.613 Z2.500 M08

G01 X61.613 Z1.641 F1.000

G01 X61.613 Z1.441 F0.140

G01 X62.000 Z1.258

G00 X62.400 Z1.458

G00 X62.400 Z1.441

( FINISH )

G00 X55.633 Z1.441

G01 X59.833 Z-0.659 F0.120

G03 X59.950 Z-0.800 R0.200

G01 X59.950 Z-9.400

G03 X59.833 Z-9.541 R0.200

G01 X58.250 Z-10.333

G01 X58.250 Z-12.550

G00 X63.000 Z-12.350

G00 X63.000 Z5.000 M09

( ******* )

( CUTTING )

( ******* )

( VACUUM LEFT ON )

G53 X0 Z0

T1034

G50 S[#130+250]

G96 M04 S#130

G00 X63.950 Z3.000 M08

G00 X63.950 Z-9.800

G01 X49.000 Z-9.800 F0.080

G00 X63.950 Z-9.800 M09

G00 X63.950 Z15.000

M31 (VACUUM ON)

M37 G04 P1.

T0303

G54

M01

(********************)

( ZERO POINT )

(********************)

G40

G10 L2 P1 W-12.85

G00 G40 W50.

(PART COUNTER UPDATE)

#110=#110+1

M99

%