The performance settings relate your machine capability with the price calculator. The faster the machine is, less time the seal production will take.

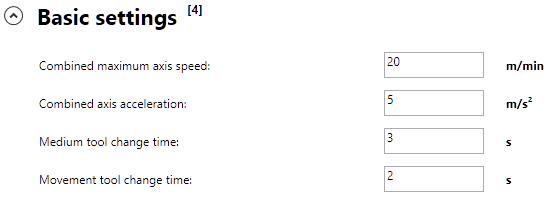

Basic settings

The first two basic settings should be taken from your machine manual. The first, named combined maximum axis speed, should be set in the units meters/minute and should reflect the maximum speed obtained when both X and Z axis are moving (combined speed).

The second setting, the acceleration will reflect on how fast the machine will achieve the maximum speed. Used units are meters / second*second.

The “medium tool change time” should be a aproximated time, in second, of the medium time taken from the machine during a tool change.

Finally the “movement tool change time”, is a approximated time that the machine takes to travel from the end position during a cycle execution until it reaches the tool change position. The longer the movement is, more time the machine takes.

Performance graphics

The performance graphics provide a insight of the machine performance based on the previous settings.

Time until maximum speed: Based on the acceleration and the maximum speed, on this graphic it can be seen the time needed to achieve the maximum axis speed.

Distance travelled during the acceleration/deacceleration: On this graphic, it is represented the distance travelled during the time that the machine is accelerating (and deaccelerating).