The operation costs on the machine settings menu plays a important role for the cost calculation of the FastQuote and on the standard costing system. All settings on this section are independent of the currency in use. If you use dollars, set them as dollars, if euros, set all in euros. This is, you are free to set the currency as your needs.

Note that the operation costs depends on the machine in use. Each machine in your organization can have different operation costs. Normally larger machines are most expensive to run and maintain, therefor generally have higher operation costs associated.

b.1) Price basic settings

- Minimum price – This price means that all production will start with this price. It can be set to zero, if no minimum price is to be used. This setting is used in the FastQuote and on the classic price calculation.

- Cost per hour – Here, the price per hour is set. Used on the classic price calculation where a rough estimate of the time to produce a product is calculated then used with this value to obtain the machining time cost.

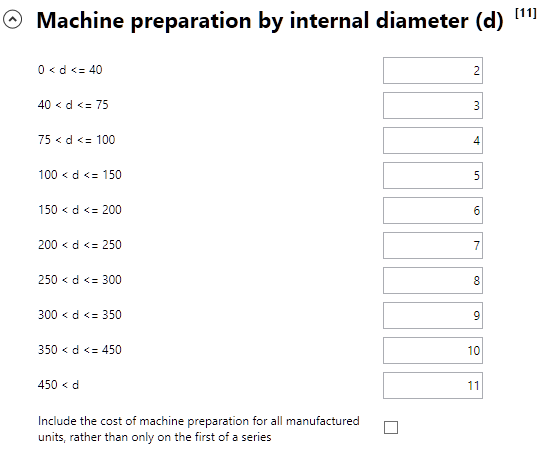

b.2) Machine preparation by internal diameter

Several costs can be associated to the inside dimension of the raw material being used. For example if a raw material to produce the part in question is 133×152, the machine preparation will be set as 5 accordingly to the table on the example below:

The machine preparation is charged only once per series, this is, if 1 part is to be produced or 60 parts the cost is the same as this setting tries to add to the parts cost the “work” developed by the machinist to prepare the machine and have it ready to produce the parts.

Since version 5.3.0.6 (Jan 2023) it is also possible to include the machine preparation cost in all seals produced. With this option set, all seals would have the preparation cost accounted into the final price.

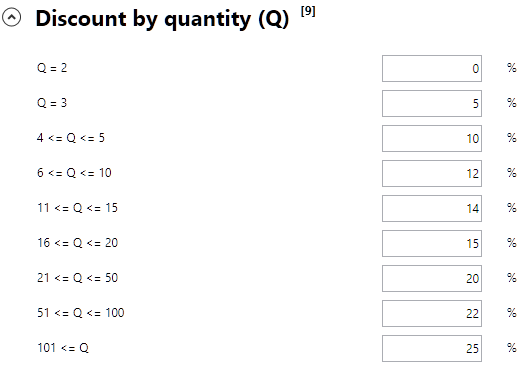

b.3) Discount per quantity

Several discounts can be set depending on the quantity being produced. Those discounts are set here.

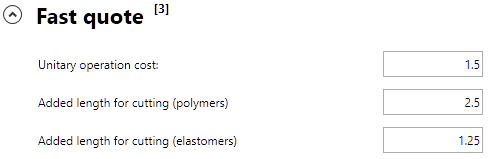

b.3) FastQuote settings

The FastQuote settings on the Operation costs menu, only affects the FastQuote quoting system. The following settings exist:

- Unitary operation cost – This defines a value to a single operation, being a operation part of the machining of a seal (a tool change). For example a guide ring normally has 4 operations (facing, inside, outside, cutting), while a rod seal has 5 operations (facing, groove, inside, outside, cutting). In this case the guide ring would have a machining cost of 4 * 1.5 = 6 and the rod 5 * 1.5 = 7.5.

- Added length for cutting (polymers) – Since the FastQuote works mostly with estimates, it does not know what tools will be used to produce a determined part, so the user must roughly indicate the amount that is needed to cut the seal. This value will be added to the length of the material used, and therefor affects the estimated price.

- Added length for cutting (elastomers) – The same as the previous, but affecting the parts made from elastomers.

A sample example would be: