On this section the code that enables movement or a sequence of events that enables a safe tool change are added.

Two sections are present – the standard safe position (that occurs always before a tool change) and the first safe position that breaks the previous rule and is executed only on the first safe position per part made. This second setting is opcional.

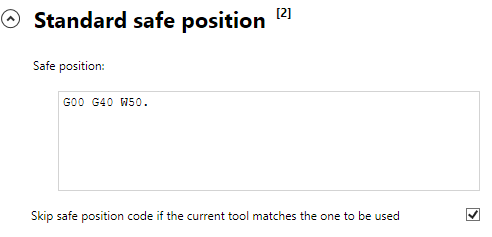

Standard safe position

Code should be added into this text box that protects the machine so that a movement is made into a location where the machine can change tools without danger. Normally the air blast commands are also placed on this code text. The option to skip the safe position if the current tool matches the one to be used, surpreses the tool change safe movement if the next tool is exactly the same as the current tool. This often happens if the facing tool is the same as the groove tool.

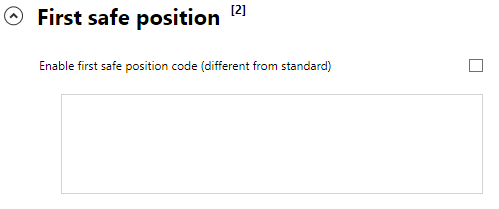

First safe position

On some configurations the initial safe position should be different from all the others. In this case enable this option and set the corresponding code. This code will be only applied on the first tool change call.