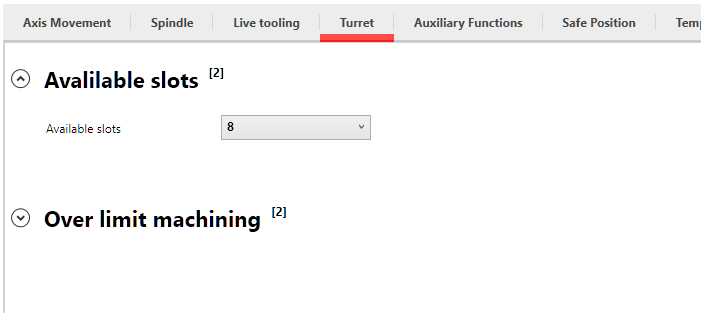

Available slots

On this setting, the number of available slots is placed on the corresponding selection box.

A custom number can also be used if there is a capacity to hold a different number of 8, 10 or 12, that are the most common set up.

Over limit machining

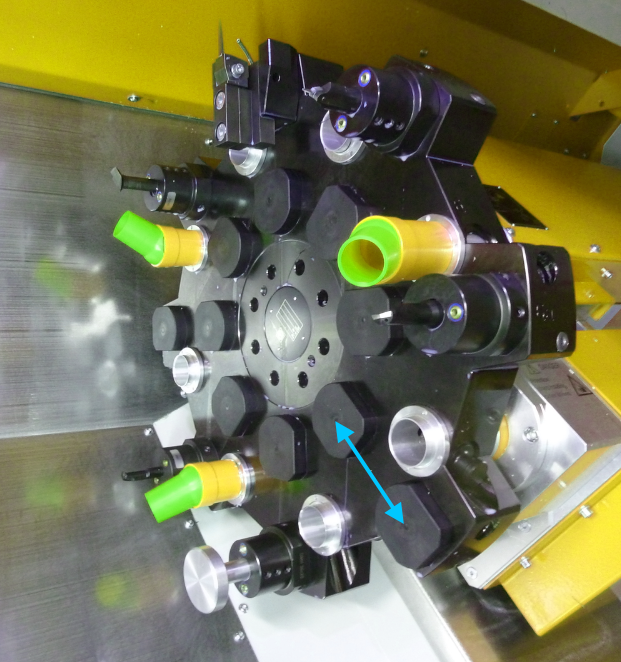

On some machine with special turrets, tooling can be placed on several locations and still use the same tool offset. This is a way to machine builders reach a higher diameter capability with smaller machines, or machines that were not build from scratch to reach such diameters.

This arrangement leads to a higher risk of interference issues if the profile being machined needs many tools, but it is suitable for the generality of the jobs.

This is normally made by offsetting the work plane so that it matches the difference between the “standard” position and the “offset” position. A example is shown below:

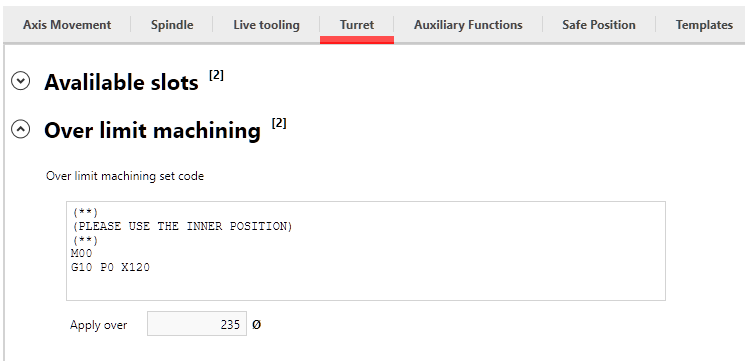

On the FastSealCreator software a option was added to handle this situation and it is located on the machine settings:

A common setting, for a Fanuc controller, would be:

(**)

(PLEASE USE THE INNER POSITION)

(**)

M00

G10 P0 X120This code will be added to the header section of the generated code and will offset all tools offsets in the value of 120mm for all seals that use a raw material with a higher diameter of 235mm (accordingly to the example).

A M00 was added to force the user to press start, as this setting is dangerous if the machinist did not changed the tools to the new location (message can also help)