In August 2022 three new tools were added to the software on the default machine.

Remember that you can import a tool into your own machine settings using the import functionality built in on the tool database. Instructions on how to import a tool from the database can be obtained here.

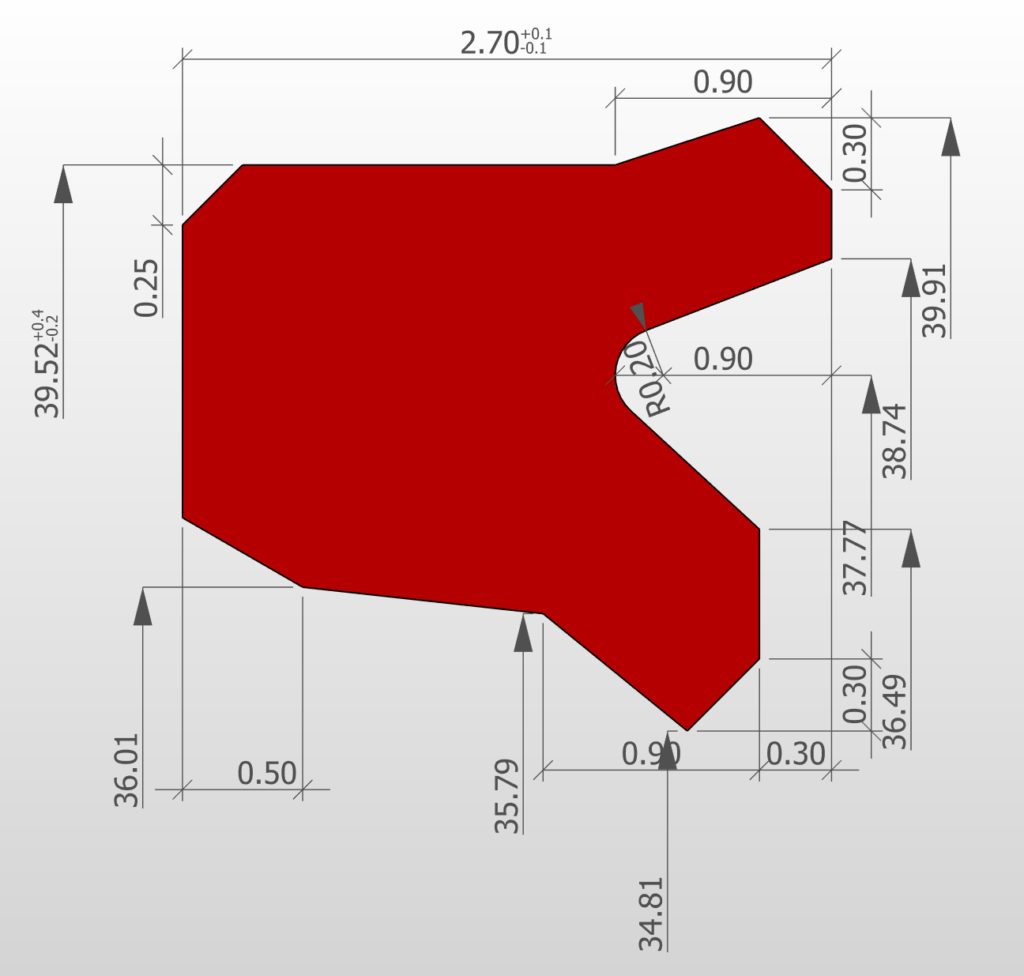

Tool 53 – Face groove micro – i503

Tool with offset 53, FastSeal reference i503, is a facing and grooving tool that allows the machining of smaller seals as the tool tip radius is just 0.2mm. Z reach is 5.5. It can be installed on the same holders as the remaining i500 series (i500, i501, ….)

Software version 5.2.8.7 already has this tool built in in selected profiles, generally associated with small grooves, like the RS01 in rubber or PU

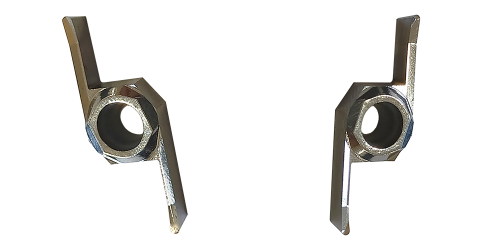

Tool 54 and 55 – Outside/Inside 0.8mm neck tool – i102 and i103

Tools with offset 54 and 55, FastSeal references i102 and i103, are outside and inside turning tools, similar to the i101 (also radius 0.4) that are grinded so that the back angle does not introduce a constrain in machining. Since the tool neck is 0.8mm the tool is structural weaker than the standard i101.

X reach is 5.5mm and we recommend the use on elastomers and on PTFE. For plastics, if used, the feed rate and cutting amount should be reduced.

Can be installed on the standard holder H100, although grinding must be carried on the holder, on the insert base until a visual inspection confirms no interference between the holder and the space that is now empty in relation to the i101 and i100.

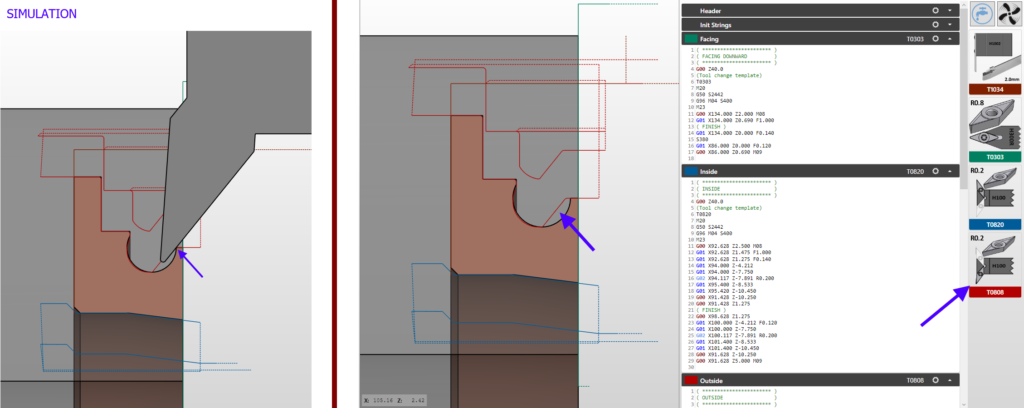

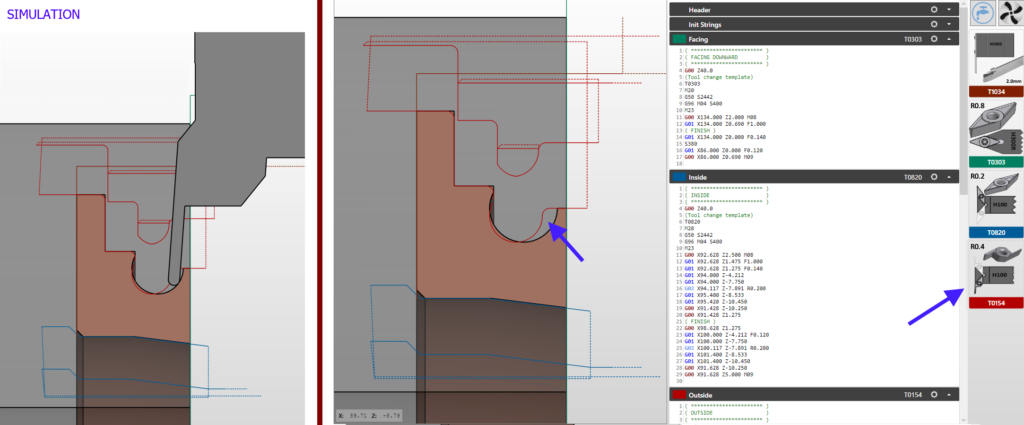

The tools are a great addition for machining profiles where the back tool constrain represents a problem, like the R34A. Below, the toolpath with the standard i100 and the new i102, where the advantages can be seen below.

Example with tool 08 (i100)

Example with tool 54 (i102)

Tools can be obtained in our online store store.fastseal.eu