Part numbers are useful when a seal present on the FastSealCreator is customized and there is a need to keep it for later use and/or to assign a part number that is generally a reference of the end client.

Any seal present on the software catalogue can be the source for a part number.

Part numbers are keep on the shared database. This means that if your organization have a database on your network, the part numbers will be accessible for all users of the software.

Part number creator example

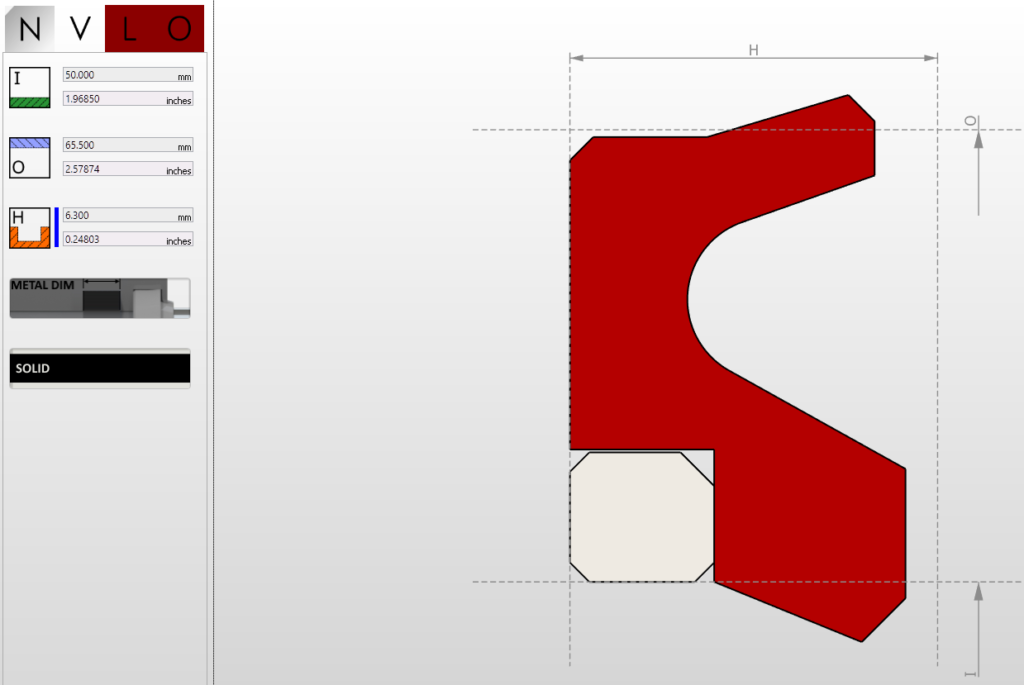

Lets create a part number based on the profile RB01 as an example. Below is the automatic calculated profile for nominals 50×65.5×6.3 metal dimension:

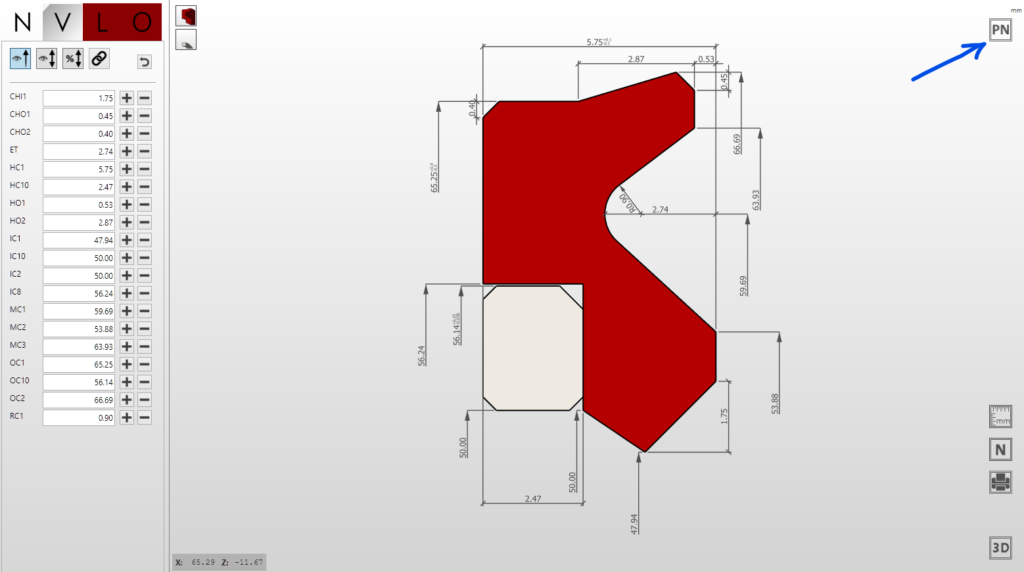

In this example, the main seal will be edited from the previous shape to:

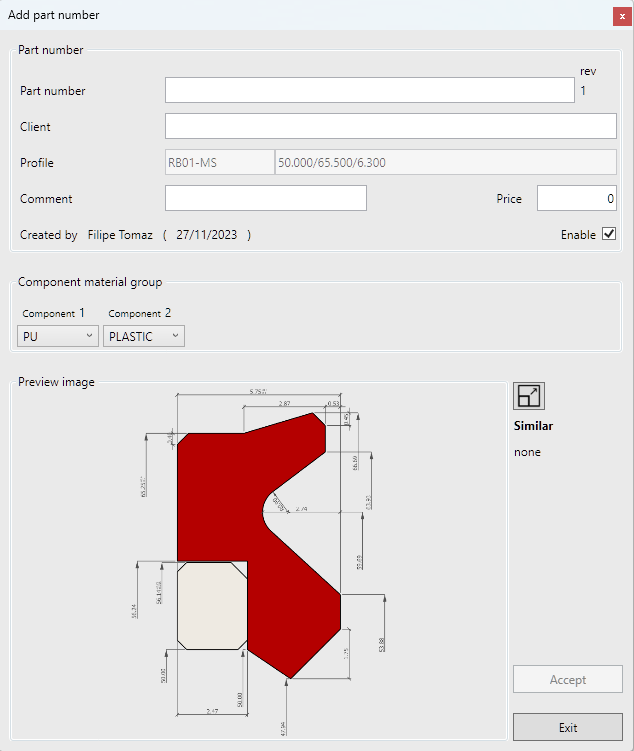

On the top right of the window a button is present with the content PN (part number). This will start the dialog to create the part number where the following dialog is present to create the part number:

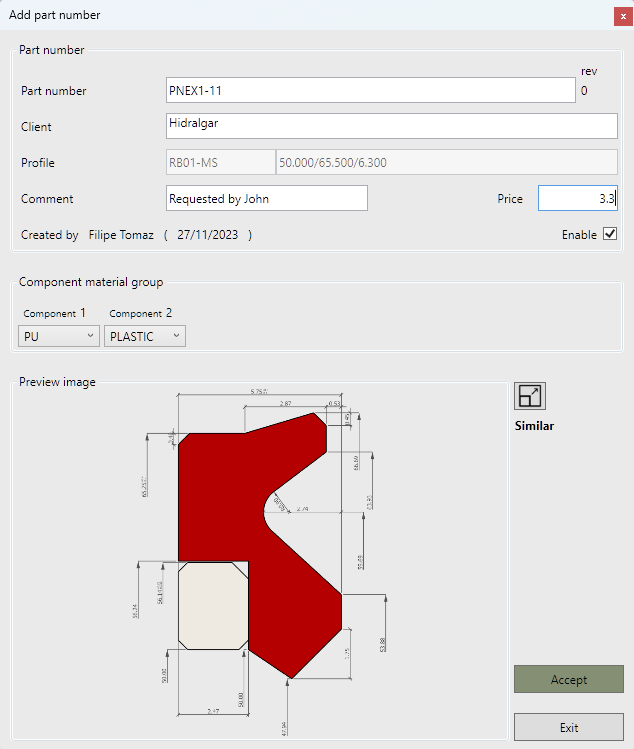

only the part number name is needed. Optionally the client name, a comment and even a cost for the part can be added. When this part number is edited a new rev (revision) number is added, so that a unique design matches a unique part number.. In this example the following information was added:

After pressing the accept, the part is created and stored on the database.

Using part numbers

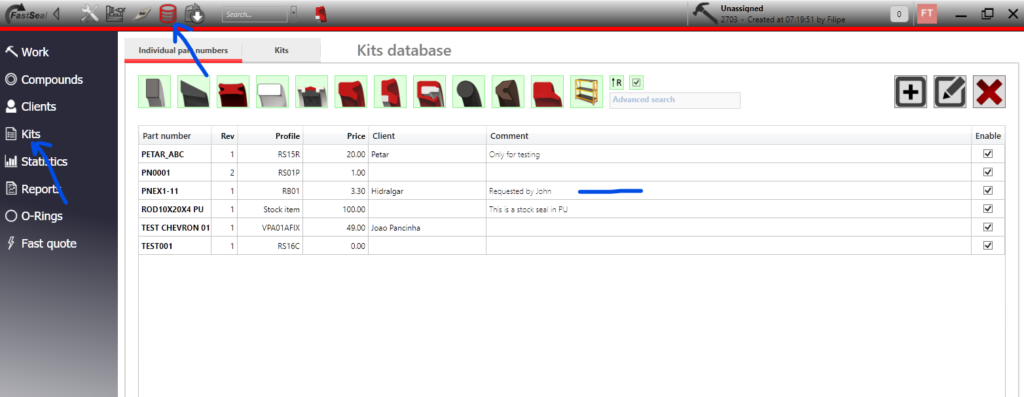

To use stored part numbers, simply use the menu present on the database that refers to kits:

Here a list of created part numbers is listed. The part number created on this example is marked.

They can be filtered based on the type of its group (rod, piston, …). By default all groups are present.

Stock parts can also be added to the part numbers and part numbers can make part of kits. Kits creation information and use can be found in:

Kits – Add and edit a kit and Kits – Add and edit kit items

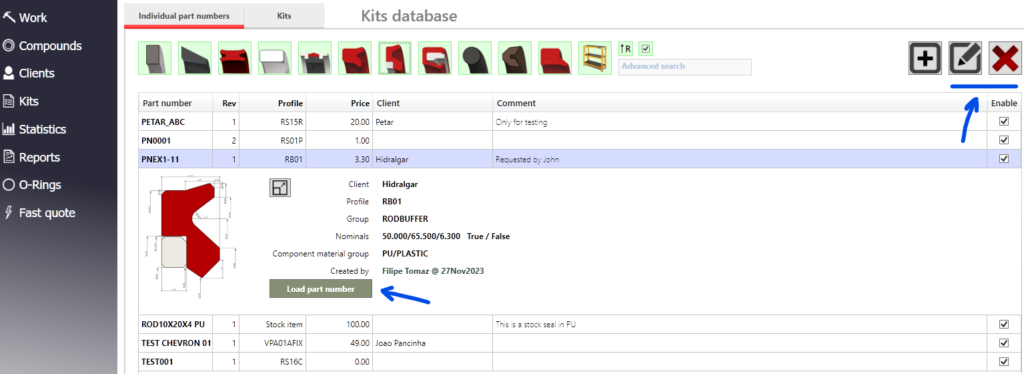

When a part number is selected, basic information is shown that helps the user to check if the selected part number is the one of interest. It can be loaded, edited or deleted using the controls marked below:

When loading the part number, the complete profile, as saved before will be loaded into the main window and the seal will be ready to be machined as normal. When machined the work database will refer to the part number, so that it keep with a reference to the unique part number.