In this post all steps are shown until reaching the GCode for the a sinumerik 810 control with linear tools

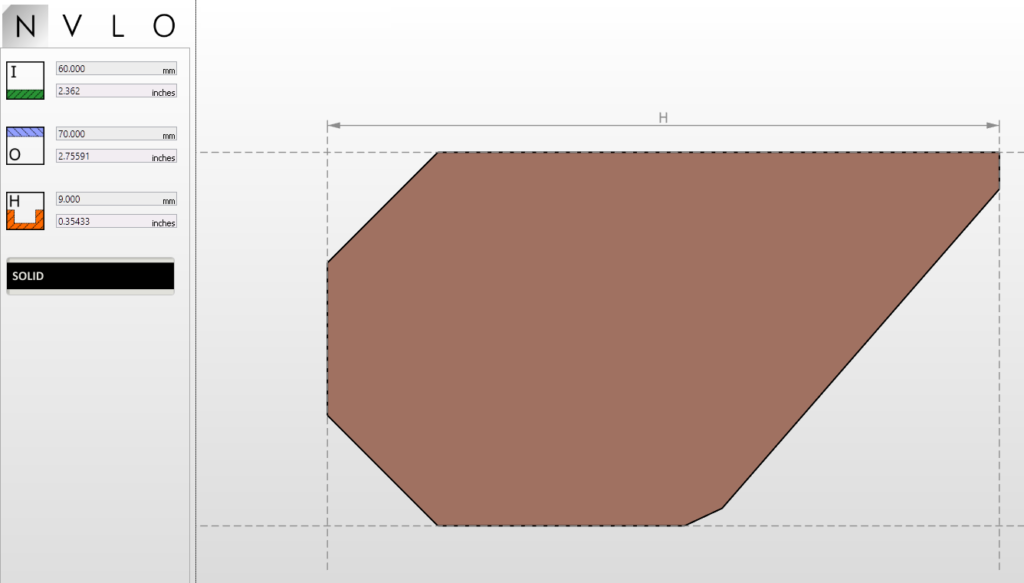

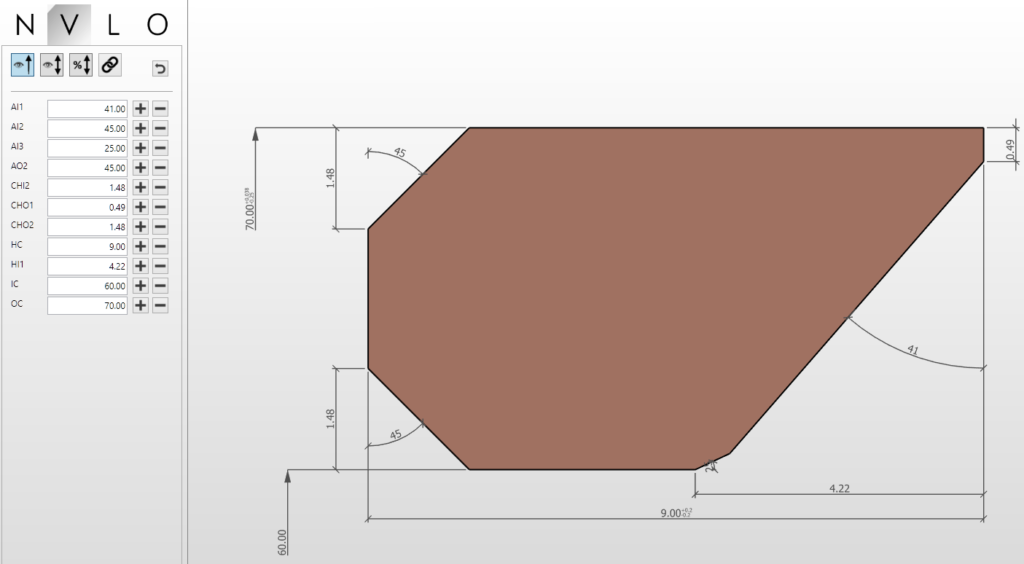

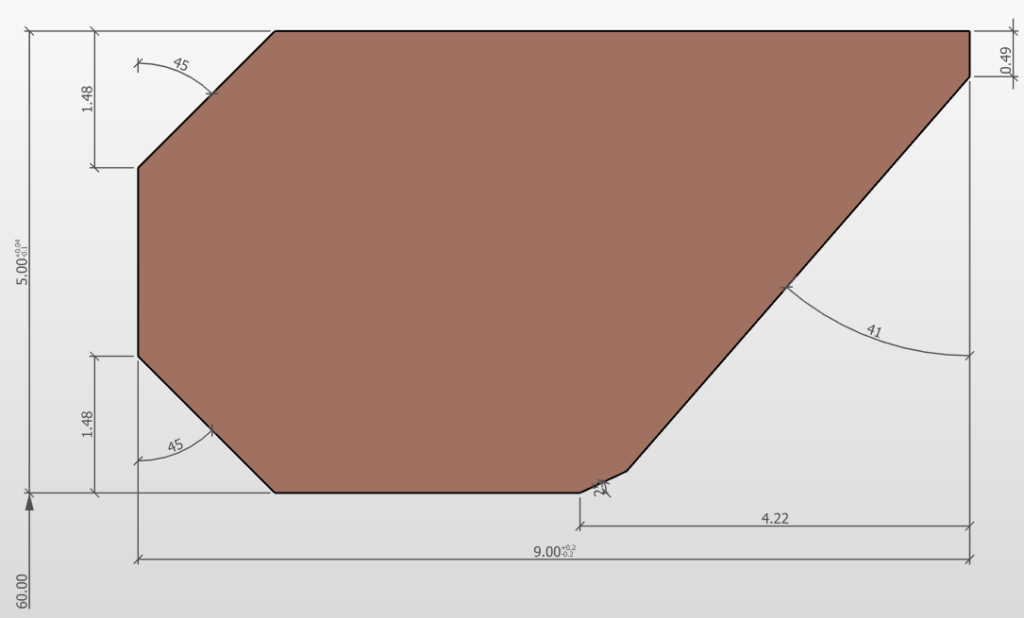

A FPES16 60x70x9 was selected.

Nominals

Variables

Diameter view

Cross section view

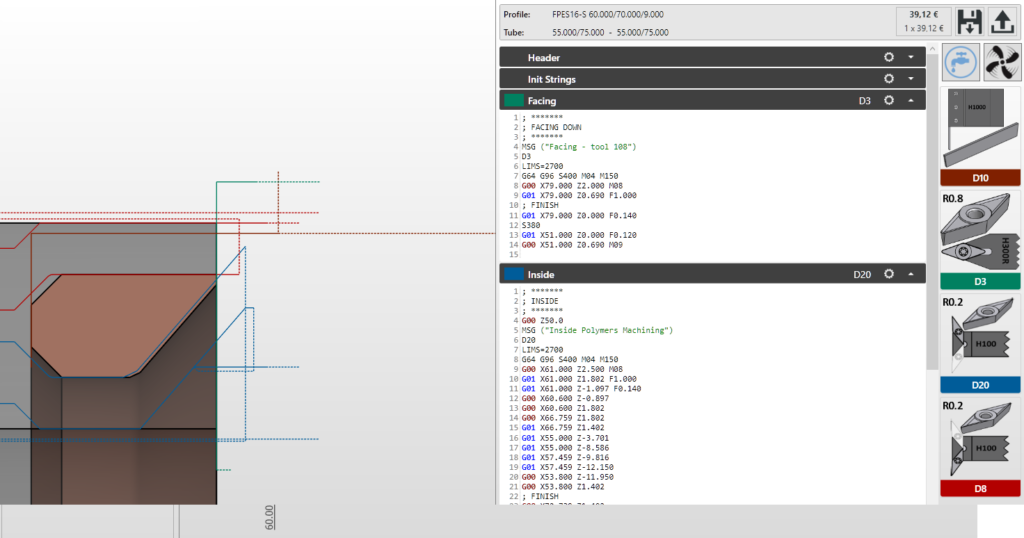

Material selection

PTFE Bronze 55×75 was selected

GCode

The code can be totally seen below that corresponds to the settings chosen.

The M-codes, header and many other features can be set up on the machine configuration. This means that the code can be adapted to the machine.

%_N_SCMAIN_MPF

;$PATH=/_N_WKS_DIR/_N_SealCAM_WPD

N10 ;-------------------------------

N20 ;FPES16-S 60.0/70.0/9.0

N30 ;-------------------------------

R10=0

R20=12.15 ;TURNINGLENGTH

R21=12.25 ;SHIFT

R22=4

R50=0

R51=0916

SC_POS01:

R23=$P_UIFR[1,Z,TR]

R24=R23-R22

IF R24<R20 GOTOF SC_POS02

TRANS X0 Z=R11

G54

SCSUB

R23=$P_UIFR[1,Z,TR]-R21

$P_UIFR[1,Z,TR]=R23

GOTOB SC_POS01

SC_POS02:

TRANS X0 Z0

G00 D0 SUPA Z550. X290.

%_N_SCSUB_SPF

;$PATH=/_N_WKS_DIR/_N_SealCAM_WPD

N10 IF ((R51==0916) OR $P_SIM) GOTOF WORK

N20 MSG("wrong NC-Mainprogram "<<R51<<"<> 0916")

N30 M0

N40 M17

N50 WORK:

; *******

; FACING DOWN

; *******

MSG ("Facing - tool 108")

D3

LIMS=2700

G64 G96 S400 M04 M150

G00 X79.000 Z2.000 M08

G01 X79.000 Z0.690 F1.000

; FINISH

G01 X79.000 Z0.000 F0.140

S380

G01 X51.000 Z0.000 F0.120

G00 X51.000 Z0.690 M09

; *******

; INSIDE

; *******

G00 Z50.0

MSG ("Inside Polymers Machining")

D20

LIMS=2700

G64 G96 S400 M04 M150

G00 X61.000 Z2.500 M08

G01 X61.000 Z1.802 F1.000

G01 X61.000 Z-1.097 F0.140

G00 X60.600 Z-0.897

G00 X60.600 Z1.802

G00 X66.759 Z1.802

G01 X66.759 Z1.402

G01 X55.000 Z-3.701

G01 X55.000 Z-8.586

G01 X57.459 Z-9.816

G01 X57.459 Z-12.150

G00 X53.800 Z-11.950

G00 X53.800 Z1.402

; FINISH

G00 X72.739 Z1.402

G01 X60.746 Z-3.811 F0.120

G02 X60.545 Z-3.944 I0.262 K-0.302

G01 X60.075 Z-4.448

G02 X60.000 Z-4.618 I0.363 K-0.169

G01 X60.000 Z-7.920

G02 X60.234 Z-8.203 I0.400 K0.000

G01 X63.459 Z-9.816

G01 X63.459 Z-12.150

G00 X54.000 Z-11.950

G00 X54.000 Z5.000 M09

; *******

; OUTSIDE

; *******

G00 Z50.0

MSG ("Outside Polymers Machining")

D8

LIMS=2700

G64 G96 S400 M04 M150

G00 X75.000 Z2.500 M08

G01 X75.000 Z1.500 F1.000

G01 X75.000 Z1.100 F0.140

G01 X75.000 Z-8.586

G01 X72.541 Z-9.816

G01 X72.521 Z-12.150

G00 X75.400 Z-11.950

G00 X75.400 Z1.100

; FINISH

G00 X70.000 Z1.100

G01 X70.000 Z-7.920 F0.120

G03 X69.766 Z-8.203 I-0.400 K0.000

G01 X66.541 Z-9.816

G01 X66.541 Z-12.150

G00 X76.000 Z-11.950

G00 X76.000 Z5.000 M09

; *******

; CUTTING

; *******

G00 Z50.0

MSG ("Polymers part off 2.5mm")

D10

LIMS=2700

G64 G96 S300 M04 M150

G00 X74.000 Z3.000 M08

G00 X74.000 Z-9.000

G01 X60.959 Z-9.000 F0.120

G00 X74.000 Z-9.000 M09

G00 X74.000 Z15.000

; Zero point calculation

G00 Z70.

MSG ("new start")

T13 D1

M01

/ M0

/ STOPRE

M17