A correct definition on the cutting limits will ensure that the tool is correctly selected by the software and that the physical limits of the tools are respected avoiding errors or crashed on the g code.

Each group of tools has a different set of settings. Explore the groups below for examples and detailed information about what the settings mean.

- Facing

- Front groove

- Outside turning

- Inside turning

- Part off

- Groove outside

- Groove inside

- Oring outside

- Oring inside

Facing tools

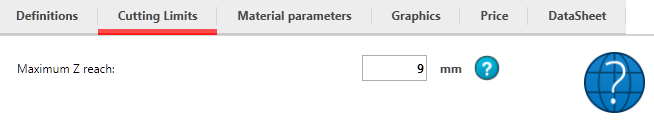

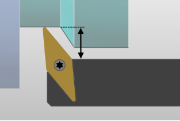

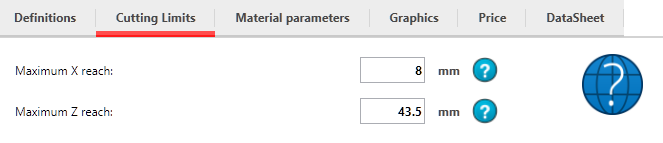

Maximum Z reach

As the name suggests, this value corresponds to the maximum reach of the tool in the Z axis. If a profile is longer than this value, the tool will not be selected. See image below for clarification.

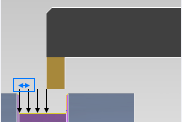

Front groove tools

Maximum X reach

Often also defined as the plunge ability, defines in radius how depth the tool can reach after its tip. See image below for clarification.

If a profile has a geometry where a higher reach in X is needed, the g code will show a warning and the machining geometry limited, but the tool can still be selected to produce the desired part.

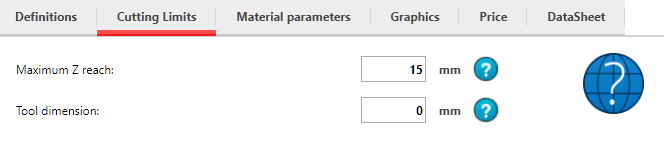

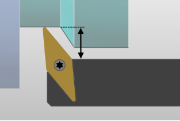

Tool dimension

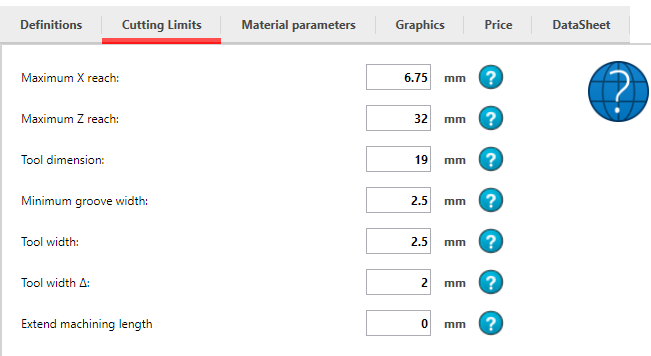

The tool dimension is the measured tool size. This dimension will be used by the g code generator, for example to limit the retract movement so that the tool does not collide with the machined material. See image below for clarification.

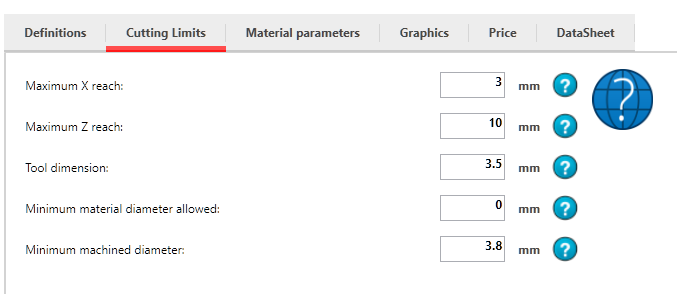

Inside tools

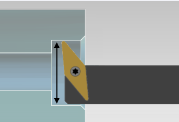

Maximum X reach

Often also defined as the plunge ability, defines in radius how depth the tool can reach after its tip. See image below for clarification.

If a profile has a geometry where a higher reach in X is needed, the g code will show a warning and the machining geometry limited, but the tool can still be selected to produce the desired part.

Maximum Z reach

As the name suggests, this value corresponds to the maximum reach of the tool in the Z axis. If a profile is longer than this value, the tool will not be selected. See image below for clarification.

Tool dimension

The tool dimension is the measured tool size. This dimension will be used by the g code generator, for example to limit the retract movement so that the tool does not collide with the machined material. See image below for clarification.

Minimum material diameter allowed

This value defines the minimum material where a determined tool can be applied. Value can be zero, meaning that the tool can machine solid materials. If a material is selected with the inside diameter less than this setting, the tool will not be used. Note that if a drill is used, the g code generator will use that information, and can still choose the tool. See image below for clarification.

Minimum machined diameter

This value defines the effective value, in diameter, that the tool can machine. This value must be equal or greater than the tool dimension setting. If a determined profile geometry is less than this setting, the tool will be rejected. See image below for clarification.

Outside tools

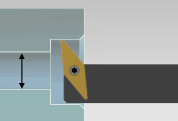

Maximum X reach

Often also defined as the plunge ability, defines in radius how depth the tool can reach after its tip. See image below for clarification.

If a profile has a geometry where a higher reach in X is needed, the g code will show a warning and the machining geometry limited, but the tool can still be selected to produce the desired part.

Maximum Z reach

As the name suggests, this value corresponds to the maximum reach of the tool in the Z axis. If a profile is longer than this value, the tool will not be selected. See image below for clarification.

Part off tools

Maximum X reach

Often also defined as the plunge ability, defines in radius how depth the tool can reach after its tip. See image below for clarification.

If a profile has a geometry where a higher reach in X is needed, the g code will show a warning and the machining geometry limited, but the tool can still be selected to produce the desired part.

Maximum Z reach

As the name suggests, this value corresponds to the maximum reach of the tool in the Z axis. If a profile is longer than this value, the tool will not be selected. See image below for clarification.

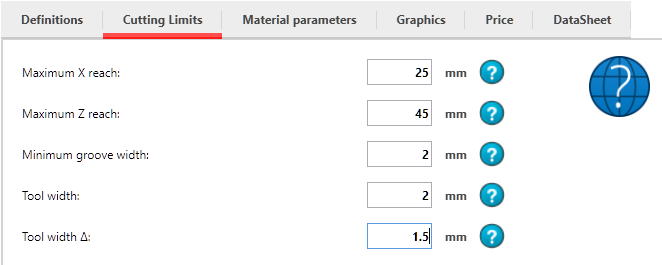

Minimum groove width

This value corresponds to the minimum groove width where the tool should be used. If the groove is smaller than the value, the tool is rejected. For example, the user could have a tool with width = 2mm, but might have interest in using it only in grooves starting at 2.5mm. In this case, the value 2.5 should be entered on this property. See image below for clarification.

Tool width

This value defines the measured tool width. See image below for clarification.

Minimum width delta

This value defines the value that after the first plunge the tool should move to make the next plunge. See image below for clarification.

Groove outside

Maximum X reach

Often also defined as the plunge ability, defines in radius how depth the tool can reach after its tip. See image below for clarification.

If a profile has a geometry where a higher reach in X is needed, the g code will show a warning and the machining geometry limited, but the tool can still be selected to produce the desired part.

Maximum Z reach

As the name suggests, this value corresponds to the maximum reach of the tool in the Z axis. If a profile is longer than this value, the tool will not be selected. See image below for clarification.

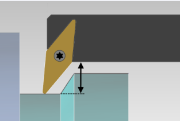

Minimum groove width

This value corresponds to the minimum groove width where the tool should be used. If the groove is smaller than the value, the tool is rejected. For example, the user could have a tool with width = 2mm, but might have interest in using it only in grooves starting at 2.5mm. In this case, the value 2.5 should be entered on this property. See image below for clarification.

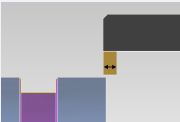

Tool width

This value defines the measured tool width. See image below for clarification.

Minimum width delta

This value defines the value that after the first plunge the tool should move to make the next plunge. See image below for clarification.

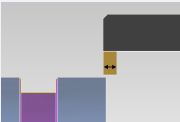

Extended machining length

This value defines the value that the outside machining should be extended so that the tool holder does not hit the material. This normally happens when the tool holder is longer than the tool cutting zone, similar to the image below.