A correct definition on the material parameters will ensure that the tool is correctly used during machining.

Each group settings can be different from the example on this web page as there are settings that are only available for a determined tool group. For example, a drill does not need different settings for finish or rough feed rates. The settings are devided on the following groups, on a similar way as the software is.

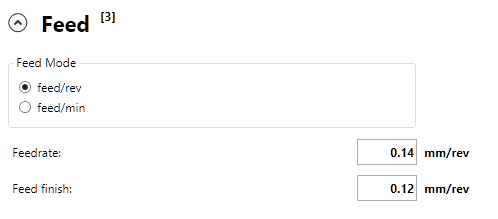

Feed

Feed mode

Most of the machines have two possibilities for the feed amount, that most of the time also depends on the tool being used. Feed/rev means amount of feed per revolution and in most of the tool documentation this is the standard way for defining a cutting tool. As the name indicates the amount will correspond to a movement of the axis to remove the amount as each spindle rotation is made.

If using feed/minute, as the name indicates, the machine will move its axis so that the requested amount of movement is made, in this case per minute.

Feed rate / finish

Depending on the tool group a finish feed and a finish feed is possible to set. On others groups only one feed type is possible.

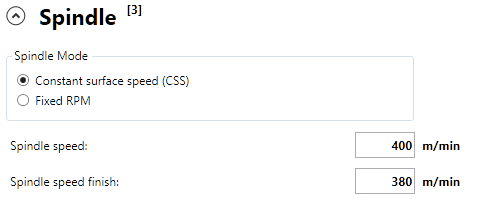

Spindle

Spindle mode

The spindle speed can be defined as constant surface speed (CSS) or as fixed rotations per minute (RPM).

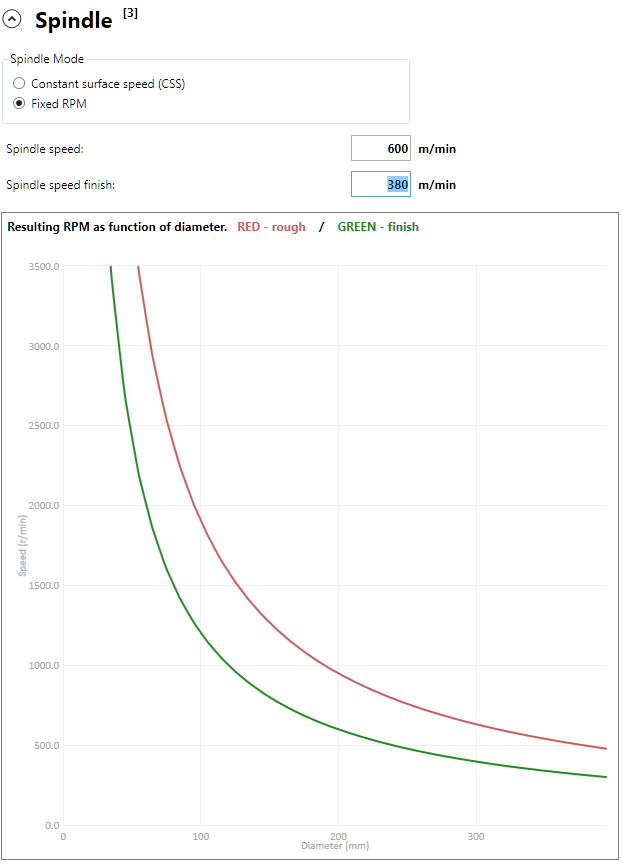

In both spindle speed modes the actual spindle rotations per minute will be calculated depending on the machining diameter, with one big difference: while in CSS mode the controller is constantly updating the spindle rotation to achieve a constant surface speed, in fixed RPM that value will be fixed until a now spindle code is set on the code. If the tool is a drilling or a mill tool, only the fixed RPM is available and the set value is the one used for that tool (no calculation is performed depending on the machining diameter).

If the user selects fixed RPM a graph will be shown to provide the user the actual spindle speed that will be set depending on the diameter.

If the rough is set to 600 m/min, at 200mm diameter the actual spindle speed will be around 1000 rpm, while the finish set at 380 m/min will result on the spindle rotating at about 600 rpm.

Note that as the diameter tends to zero, the spindle speed increases dramatically. It is important to set the maximum spindle speed on the machine configuration so that a safe RPM value is not exceeded.

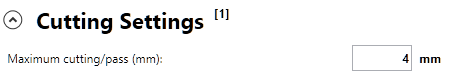

Cutting settings

Maximum cutting/pass

Defines the maximum mm per pass the tool produces. This value will also be applied to rough and finish passes, and can be changed on the code window when the code is generated.

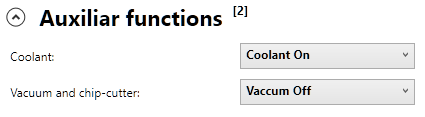

Auxiliar functions

Coolant

Sets if the coolant should be used for this tool as default.

Vacuum

Sets if the vacuum should be used for this tool as default.

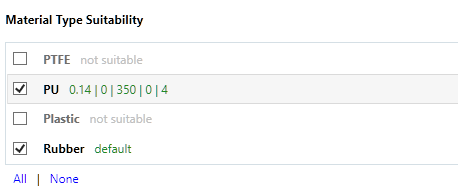

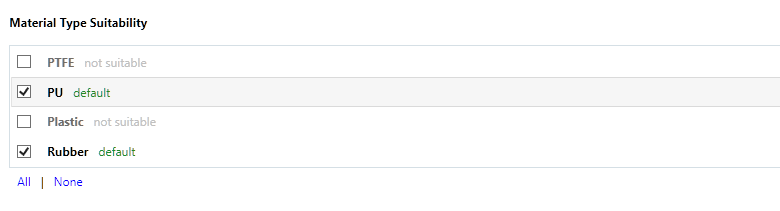

Material type suitability

Most of the settings can also be set individually for each type of material. On this menu is possible to set individually the settings for PTFE, PU, Plastics and Rubbers. The user can set the tool as suitable to machine a determined material, or the tool can be marked as unsuitable for that material. If unsuitable, the g code generator will not select the tool.

A tool that is suitable for a determined material is marked with the ‘check’ symbol before the material type.

When the default settings will be used to machine a material the word ‘default’ will be shown as it is on the example.

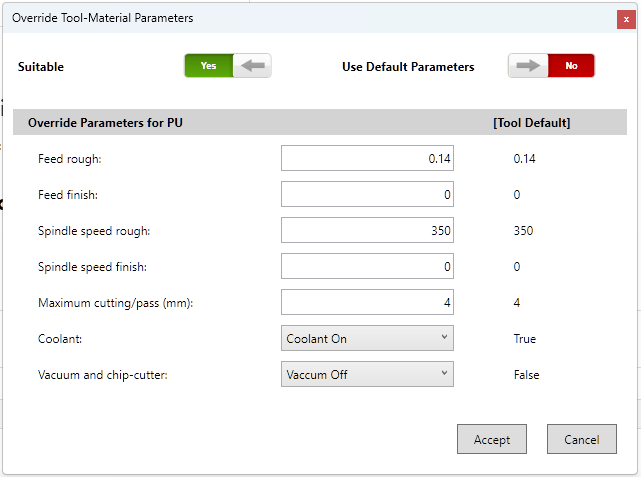

Set specific material parameters

If different settings are to be used for a determined tool/material, pressing the default button (green text) will present the following menu:

To edit the parameters, the “use default parameters” setting must be set as “no”.

The settings defined here will be then used only when the material in question is being machined. For all other materials, in no manual setting is created, the default settings will be used. Once the default settings are changed, the new settings are shown: