If you already have a CNC lathe then you already have the most important part of a seal making lathe. The rest, we can supply.

There are components that are recommended but not necessary at start and can be bought when the process of producing seals is already ongoing on your company. The list of items can be resumed to:

- FastSealCreator software – needed

- Basic tool package – highly recommended

- Manual chuck + clamps – recommended

- Vacuum unit – recommended

- Chip cutter – recommended depending on the machine

FastSealCreator software

The software generates the code to be used on your machine.

Typically the software is installed on a PC near the machine and is configurated to produce code that is fully compatible with the control present on the machine. Any modern or old control can be used with the FastSealCreator software, so you can use the software on a machine build in 2022 or in 1978. More information can be obtained in www.fastseal.eu

The FastSealCreator software currently have 2 versions: full version and a office version. The difference between them is that the office version is not able to generate code.

Software have a subscription plan. Please check subscription plan for more information.

Order resumed table

For ordering and cross reference the following table sumarizes all the parts:

| Item description | Quantity |

| FastSealCreator software license | 1 |

| FastSealCreator software office license | 1 |

Basic tool package

There are currently many different tools on the FastSeal catalogue. Some of those tools are used on uncommon seals or in special sizes. Therefor to minimize the cost of a complete tool system, we have selected the tools that are commonly used and we called that selection the basic tools package. This basic tool package ensures that you will have the widest range of tools at the best possible cost.

Please check: Basic tool package content

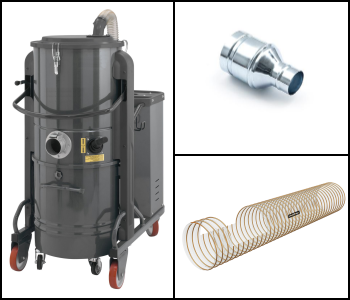

Vacuum unit

The vacuum unit is responsible for removing the chips from the machining area. This will result on a better surface quality and longer tool life. It will also reduce the machining time as the operator will not need to stop the machining often.

We recommend the use of a powerful vacuum system, and therefor we use 5.5Kw vacuums.

To complement the offer, we can also supply vacuum tubes with inner diameter 70mm, adequate for coolant liquid that are reinforced with helicoid steel and a adaptor between the vacuum unit and the tube.

Order resumed table

For ordering and cross reference the following table sumarizes all the parts (items with links will open the store page):

| Item description | Quantity |

| 5.5Kw vacuum for 400VAC 3phases with stainless steel container | 1 |

| 5.5Kw vacuum for 400VAC 3phases with steel container | 1 |

| 5.5Kw vacuum for 230VAC 3phases with stainless steel container | 1 |

| 5.5Kw vacuum for 230VAC 3phases with steel container | 1 |

| Reducer for flexible tube PU + metal | 1 |

| PU tube + metal (choose in meters) | min 1, max 15 |

Chip cutter

If the vacuum suction nose can be placed near the cutting zone and does not interfere with the machining, then it should be used as it is. A good example of this application is the FastSeal5 machine where there is no interference between the tooling and the vacuum tube.

In other situations, the vacuum tube is generally located near the turret and during the movement of the turret is not possible to maintain a good vacuum position.

In those situations a chip cutter might be helpfully. We can supply such units and its documentation can be found in : chip cutter user manual

The adaptation of the chip cutter unit to the machine must be done by the end customer and generally it requires plate cutting and welding to produce a support that also serves as a cover for the belt.

We can also supply flexible tubes that are generally connected or to the chip cutter or to the tool holder.

This adaptation must be carried at the customer location.

Order resumed table

For ordering and cross reference the following table sumarizes all the parts (items with links will open the store page):

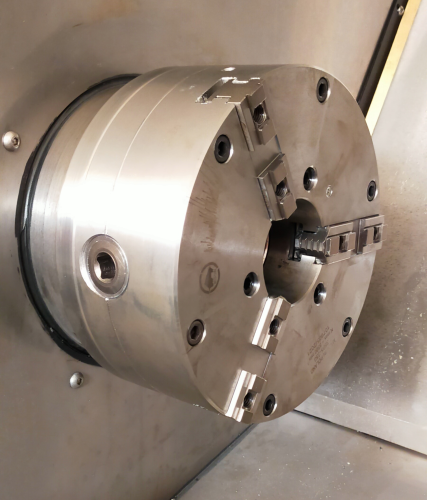

Manual chuck

Most of the CNC lathes available in the market are supplied with a hydraulic chuck. This type of chuck is the best for repetitive metal work, but not adequate for tightening the raw material for seals. Two main reasons:

- Very low clamp travel, meaning that the dimensions cannot vary without time consuming adjustments

- High clamping for not adequate for thin, flexible materials

To overcome this situation we implemented the use of a manual chuck and special clamps made to suite the manual chuck. This chuck, manufactured by Bison Bial, is produced in Poland and the model used is the 250mm diameter, steel body able to rotate at 3500 rpm’s. The clamps that we supply are only compatible with the 250mm diameter chuck.

We also can supply the master jaws for the chuck. The master jaws then receive the aluminium clamps. The master jaws are equiped with special M12 screws with a lower head suitable to receive the aluminium clamps.

Chuck and master jaws installed during a retrofit:

To install the chuck into your machine the plate between the chuck and the spindle cone must be either manufactured or bought if available. Since the spindle cone depends on the machine we do not stock this item.

Special long keys can also be supplied on demand.

Order resumed table

For ordering and cross reference the following table sumarizes all the parts:

| Item description | Quantity |

| Bison chuck 250mm steel body, maximum 3500 rpm | 1 |

| Master jaws for Bison 250mm diameter. One set has 3 master jaws and 6 screws | 1 set |

| Long key for Bison chuck. Inform the length required | 1 – inform length required |

| Adaptor plate for A2-6 spindle | 1 |

Aluminium clamps

We manufacture and supply the clamps compatible with the Bison 250mm chucks/master jaws.

The full range of clamps can be seen on the page: Aluminium clamps range