Fast Seal 5

Concept

-

Fast Seal 5 design reflects our many years of experience working with seals. Having a wide base of customers located all around the word, we have considerable knowlage about the needs and challenges workshops face, whether they are established enterprises or new companies, who are just venturing into the seal business.

-

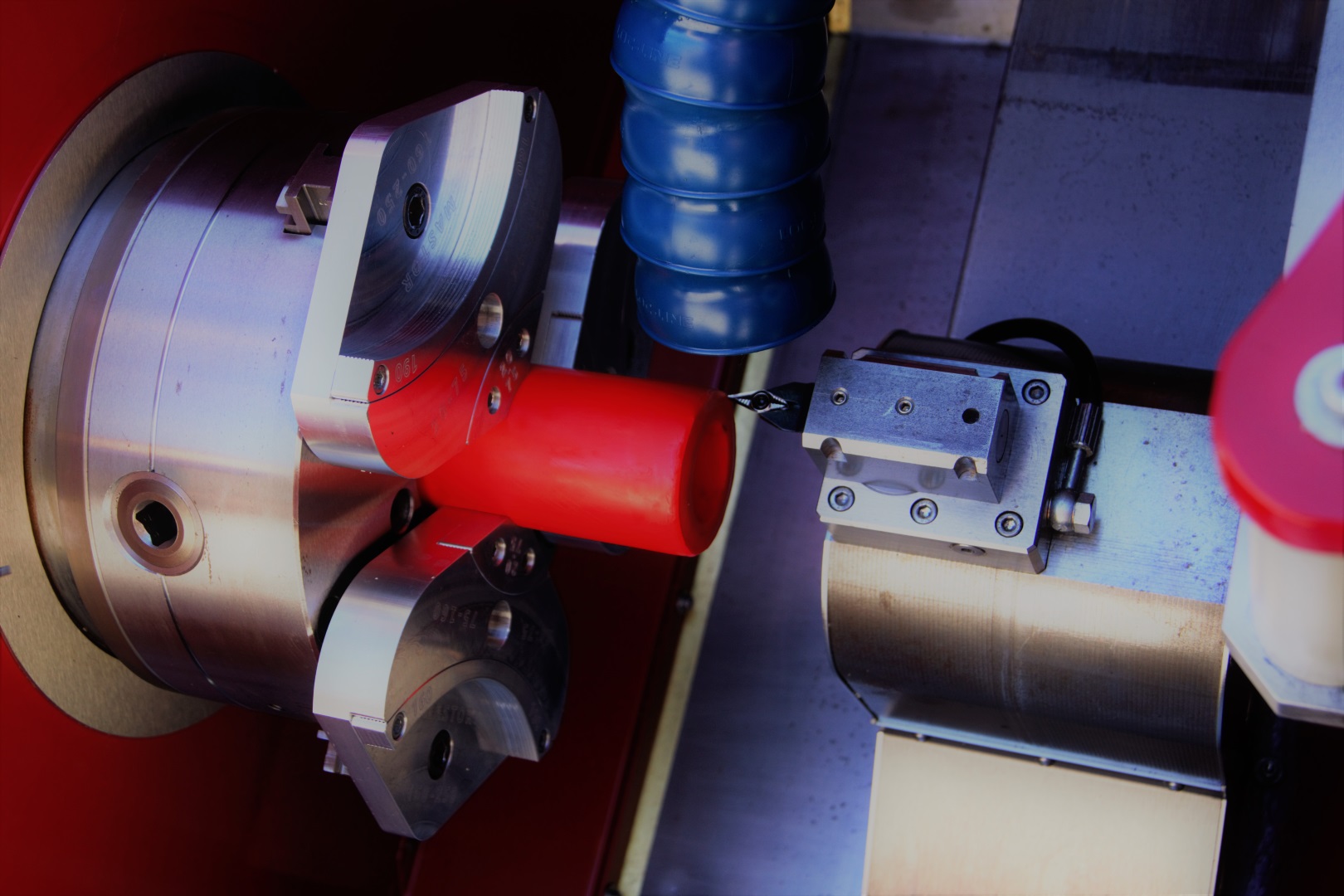

Fast Seal 5 is built from scratch at our workshop the process is entirely carried out here, by our own personal. We do not work with subsidiaries nor assemble parts made in other countries. This results in a machines 100% made in Portugal, Europe with attentive and demanding supervision and quality control, to assure a high-quality product that can meet high standards of quality.

Specifications

Tool system

- 30 tool stations

- 20 mm tool diameter

- Special turning tool shank

- No tool-to-tool interference

Other information

- Overall dimensions: (L x W x H) 2150 x 1560 x 1780 mm

- Coolant tank capacity 80 L

- Machine weight 3000 kg

Includes

- Air blast

Optional

- Vacuum 5.5 kW

- Instalation and training at client location

Base

- Power supply voltage 3x400V +6% -10%, 50Hz + neutral

- Power supply voltage 3x220V +6% -10%, 60Hz

- 17 KVA (including vacuum unit 5.5 kW)

Capacity

- Maximal turning diameter over bed of 600 mm (23.5 inch)

- Maximal turning length of 240 mm

- Diameter of standard 3-jaw chuck 250 mm/bar 75 mm

Headstock

- Spindle motor power 7.5kW - direct drive

- Spindle speed range 30 - 3500 rpm

- Maximum spindle torque 47 Nm

Axis

- X axis travel 330 mm

- Z axis travel 600 mm

- X axis traverse 26 m/min

- Z axis traverse 26 m/min

Advantages

Excellent price-performance ratio

FastSeal 5 has the best price for any high-quality seal machine on the market. Lower cost machines are simply not reliable, have poor design and subpar components.

No binding contracts

By acquiring a FastSeal 5, you are not bound to our tools or our materials. The freedom to choose suppliers is a great advantage for starting businesses, as these contracts tend to be a burden for companies with limited budgets.

Support and assistance

Mastor guarantees support and assistance if any problem arises. We have a team of dedicated technical staff widely available to assist you in case some issue comes up. Our remote assistance enabled controller is also a great advantage to locate and solve problems.

Simplicity

Using a seal making machine should not be the same as using an airplane. Our machine only have the needed controls to make your work simpler. Less confusion corresponds to more productivity.